El término PU se refiere a un tejido recubierto o fabricado con poliuretano. Su textura suave y flexible se utiliza a menudo en productos que requieren impermeabilidad y transpirabilidad, como impermeables y ropa de exterior.

El tamaño del mercado global alcanzó los USD 87,10 mil millones en 2023, con un fuerte crecimiento proyectado hasta 2032.

Los fabricantes prefieren los textiles de PU por su comodidad, control de la humedad y versatilidad, especialmente en aplicaciones de muebles y automóviles.

El tejido de PU está hecho de poliuretano y ofrece una tela suave y flexible Ideal para productos resistentes al agua como impermeables y equipos para actividades al aire libre.

El mercado mundial de textiles de PU está creciendo rápidamente y alcanzó los 87,10 mil millones de dólares en 2023, lo que indica una fuerte demanda en diversas industrias.

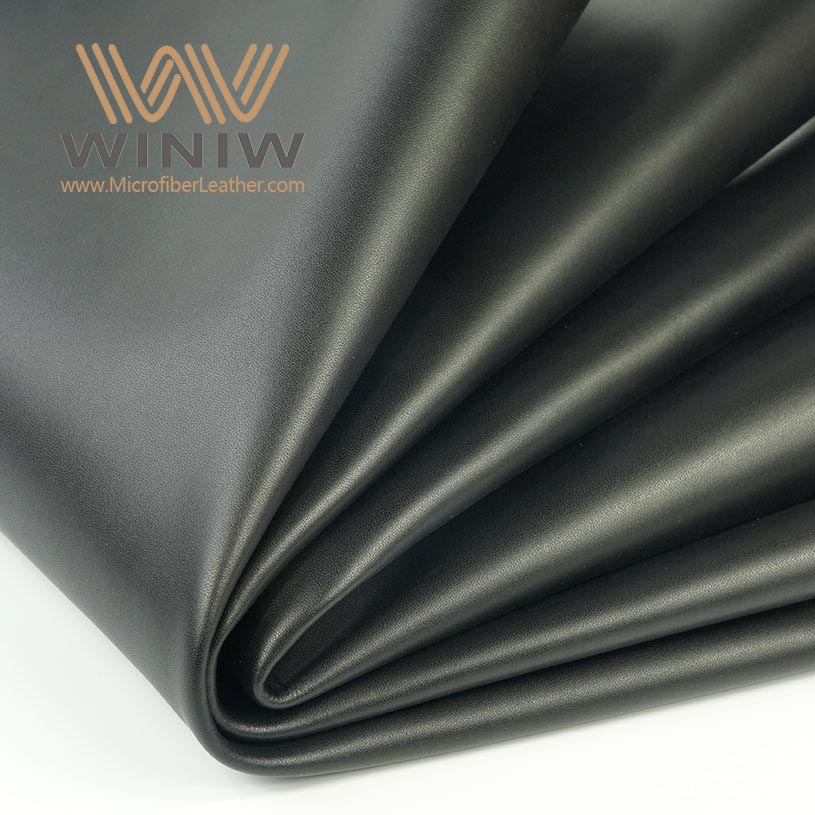

El cuero de PU imita el cuero genuino Su aspecto y tacto son más asequibles y fáciles de mantener, lo que lo hace popular en la moda y en los interiores de los automóviles.

Los textiles de PU proporcionan una excelente durabilidad, resistencia al agua y transpirabilidad, lo que los hace adecuados para equipos de exterior y artículos de uso diario.

Al elegir textiles de PU, tenga en cuenta el tipo de revestimiento y sustrato, ya que estos factores afectan la durabilidad, la comodidad y el rendimiento.

La sustentabilidad es un enfoque cada vez mayor en la producción de textiles de PU, con opciones de base biológica y sistemas a base de agua que reducen el impacto ambiental.

Los textiles de PU son versátiles y se utilizan en moda, tapicería, equipamiento para actividades al aire libre y aplicaciones automotrices, combinando estilo con beneficios prácticos.

El cuidado regular y el mantenimiento adecuado pueden prolongar la vida útil de los textiles de PU, evitando problemas como agrietamiento y descamación con el tiempo.

El poliuretano, a menudo llamado PU, es un polímero versátil que desempeña un papel crucial en los textiles modernos. El PU se encuentra en muchos productos porque los fabricantes valoran su adaptabilidad y rendimiento. Cuando se pregunta "¿qué es el PU?", se refiere a un material creado mediante la unión de unidades orgánicas con enlaces carbamato. Este proceso implica la reacción de un isocianato polimérico con un poliol, lo que produce copolímeros alternados. Las propiedades del PU varían según los tipos de isocianatos y polioles utilizados. Esta flexibilidad permite encontrar PU en aplicaciones que abarcan desde espumas blandas hasta fibras duraderas.

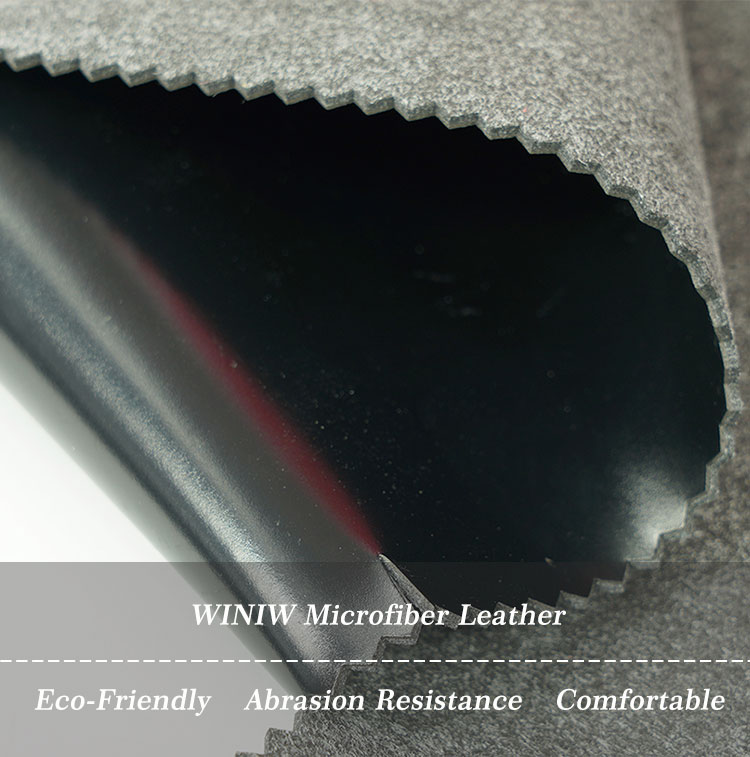

Los textiles de PU se refieren a telas que utilizan poliuretano como revestimiento o como material principal. Los textiles de PU se encuentran en ropa impermeable, ropa deportiva y tapicería porque ofrecen resistencia al agua y transpirabilidad. Los fabricantes aplican una fina capa de PU a una tela base, como poliéster, nailon o algodón. Esta capa le da al textil un acabado suave y aumenta su durabilidad. Los textiles de PU se benefician porque combinan comodidad con características prácticas como control de la humedad y flexibilidad.

El poliuretano es una clase de polímeros hechos de unidades orgánicas unidas por enlaces carbamato (uretano).

Se produce mediante la reacción de un isocianato polimérico con un poliol, dando lugar a copolímeros alternados.

Las propiedades del poliuretano están influenciadas por los tipos de isocianatos y polioles utilizados, lo que permite una amplia gama de aplicaciones en textiles, incluidas espumas y fibras flexibles.

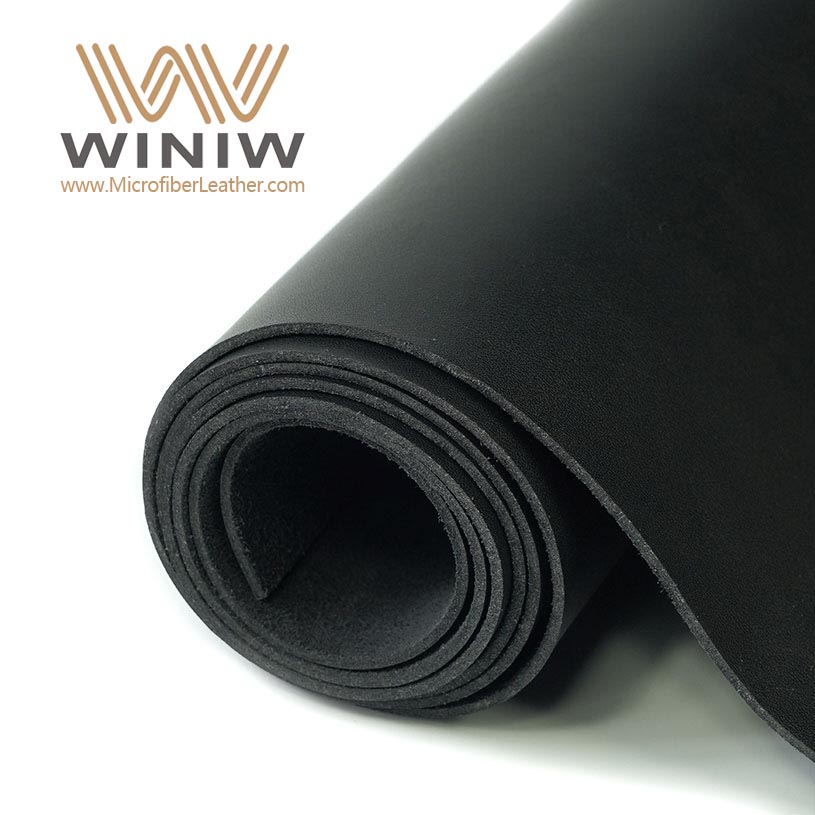

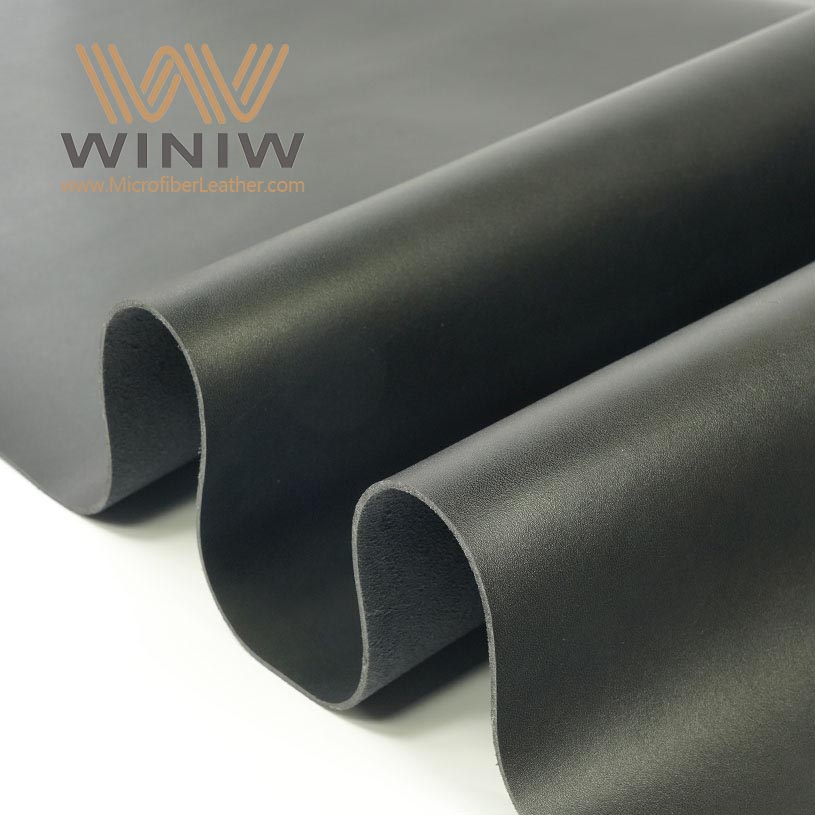

Cuero de PU Es un tipo específico de tejido de PU diseñado para imitar la apariencia y el tacto del cuero genuino. Cuero de PU En moda, muebles e interiores de automóviles. Los fabricantes crean cuero PU aplicando una capa de poliuretano a un soporte de tela, generalmente poliéster o algodón. Este proceso da como resultado un material suave y flexible. El cuero PU ofrece mayor resistencia al desgaste, lo que lo convierte en una opción popular para artículos que requieren durabilidad y estilo.

|

Característica |

Cuero de PU |

Otro cuero de imitación (por ejemplo, PVC) |

|---|---|---|

|

Composición |

Capa de poliuretano sobre soporte de tela (poliéster/algodón) |

Diferentes materiales base (por ejemplo, PVC) |

|

Durabilidad |

Mayor resistencia al desgaste |

Puede agrietarse o pelarse con el tiempo. |

|

Experiencia táctil |

Más suave, más flexible, imita el cuero genuino. |

Textura más firme y menos natural. |

|

Transpirabilidad |

Menos transpirable debido al denso revestimiento de poliuretano. |

Varía, algunos pueden tener mejor flujo de aire. |

|

Costo |

Generalmente más alto debido a la calidad |

A menudo más bajo, especialmente para las opciones básicas de PVC |

Observarás que el cuero PU destaca por su textura suave y flexibilidad. Resiste mejor el agrietamiento y el descascarillado que muchas otras pieles sintéticas. También verás que el cuero PU suele ser más caro debido a su calidad y rendimiento.

Mucha gente malinterpreta los materiales de PU, especialmente al compararlos con el cuero genuino u otros materiales sintéticos. Es posible que escuche afirmaciones sobre la falta de durabilidad o comodidad del cuero PU, pero estas afirmaciones a menudo ignoran los avances en la fabricación y la ciencia de los materiales.

Mito 1: El cuero PU no es duradero. Quizás creas que el cuero PU es menos duradero que el cuero animal, pero su durabilidad depende de la calidad y el mantenimiento.

Mito 2: El cuero PU es incómodo. Aunque no siempre se siente como cuero genuino, puede ser suave y cómodo si los fabricantes utilizan el grosor y la flexibilidad adecuados.

Mito 3: El cuero PU es muy susceptible a desgarros y perforaciones. El cuero PU de alta calidad resiste desgarros y perforaciones, especialmente cuando se produce con procesos avanzados.

Consejo: Al elegir telas o cuero de PU, revise las especificaciones del producto y los detalles de fabricación. Los materiales de PU de alta calidad ofrecen un excelente rendimiento y comodidad.

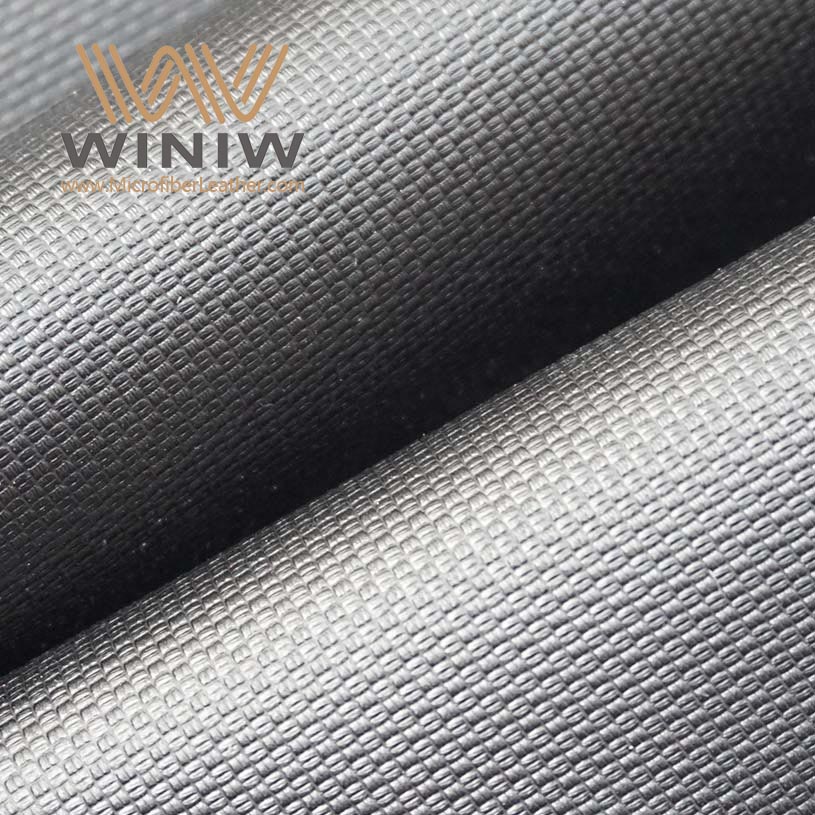

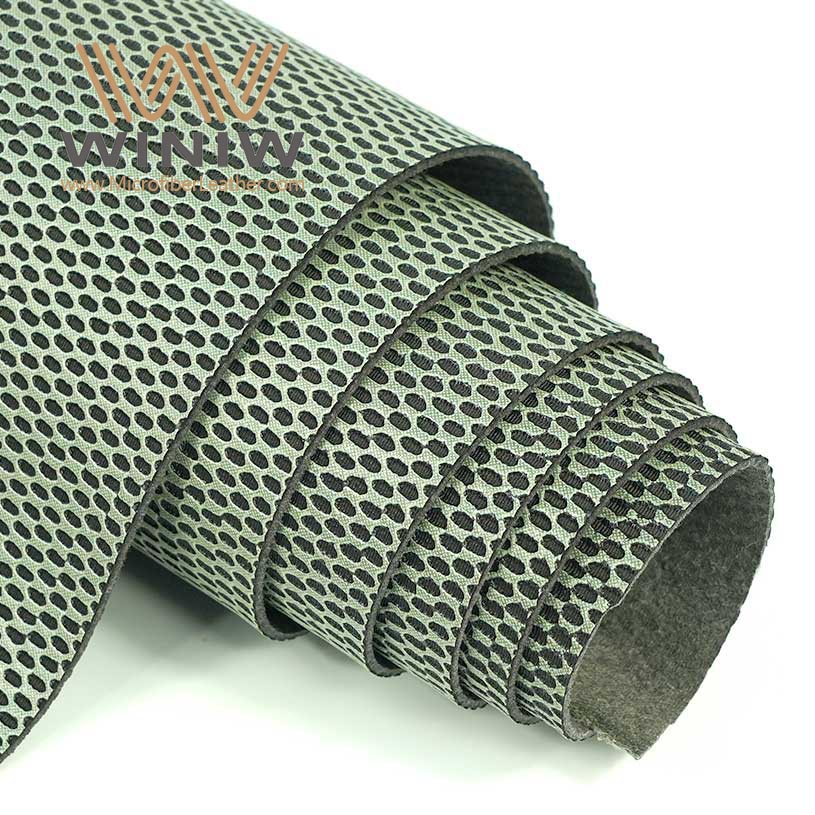

Te encuentras con Tejido recubierto de PU Se utiliza en una amplia gama de industrias debido a su impresionante durabilidad y versatilidad. Los fabricantes aplican una capa de poliuretano a un material base, que puede incluir fibra de vidrio, poliéster o algodón. Este proceso crea un tejido resistente al agua, la abrasión y los productos químicos agresivos. Cuando se necesitan materiales para aplicaciones de alta resistencia, como cubiertas industriales o ropa de protección, a menudo se opta por tejidos recubiertos de PU. La base de fibra de vidrio en algunos tejidos recubiertos de PU proporciona una excelente resistencia a la tracción y aislamiento térmico. El recubrimiento de poliuretano mejora la impermeabilidad y la durabilidad general, lo que hace que estos tejidos sean adecuados para entornos donde la resistencia y la resiliencia son fundamentales.

Nota: Las telas recubiertas de PU superan a muchas alternativas en condiciones difíciles, pero siempre debes verificar el material base para asegurarte de que satisfaga tus necesidades específicas.

El tejido 100 % PU está compuesto íntegramente de poliuretano, sin soporte textil. Este tipo de material se encuentra en productos que requieren una sensación suave, similar al cuero, y una gran flexibilidad. Si bien el tejido 100 % PU ofrece una superficie lisa y una apariencia uniforme, puede no igualar la resistencia y resiliencia de los tejidos recubiertos de PU, especialmente en entornos exigentes. Es frecuente encontrar tejido 100 % PU en accesorios de moda, chaquetas ligeras y artículos decorativos. Si prioriza la comodidad y la apariencia sobre el rendimiento resistente, el tejido 100 % PU puede ser una excelente opción.

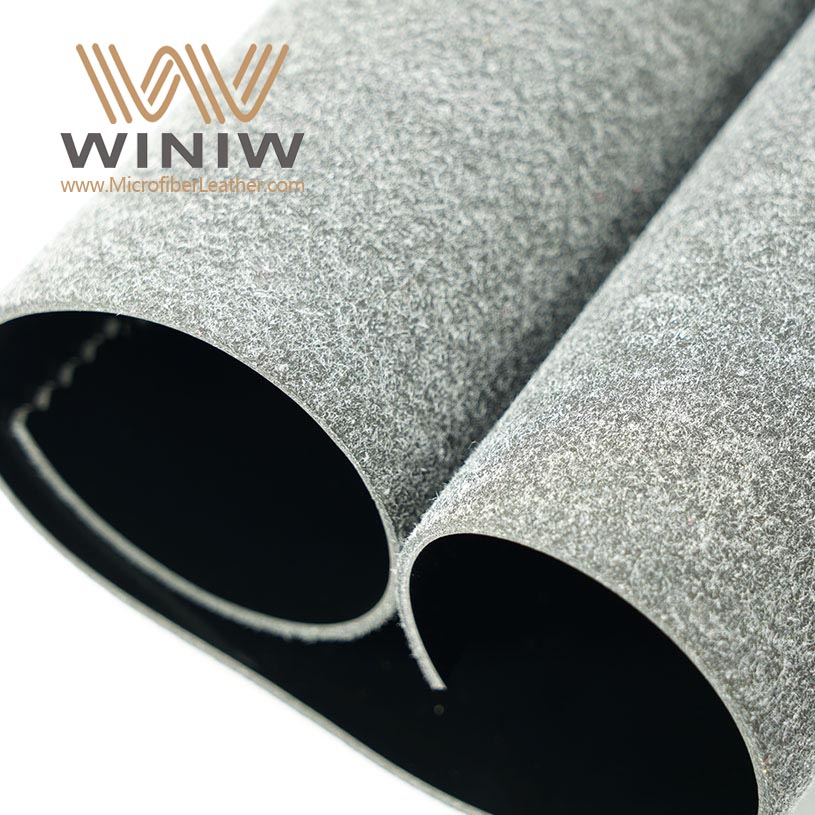

El sustrato, o material base, desempeña un papel crucial en el rendimiento de los textiles de PU. Puede elegir entre varias opciones comunes, cada una con ventajas únicas:

El poliéster es un sustrato popular para textiles de PU. Se beneficia de su excelente relación calidad-precio y amplia disponibilidad. Los recubrimientos de poliuretano a base de poliéster ofrecen flexibilidad y durabilidad, lo que los hace ideales para productos de uso diario como bolsos, ropa impermeable y tapicería.

Los sustratos de nailon proporcionan mayor resistencia y resistencia a la abrasión. Si necesita telas recubiertas de PU para equipos de exterior o deportivos, las opciones con refuerzo de nailon ofrecen un rendimiento superior. La combinación de nailon y poliuretano crea un material ligero pero resistente que soporta el uso frecuente.

Los sustratos de algodón proporcionan una base suave y transpirable, ideal para prendas y accesorios. Cuando los fabricantes aplican un recubrimiento de poliuretano al algodón, se obtiene una tela que se siente cómoda al tacto y que conserva la resistencia al agua. Las telas con recubrimiento de PU a base de algodón son ideales para ropa casual y prendas que requieren un toque natural.

Otras opciones de sustrato incluyen:

Poliéster reciclado: Respetuoso con el medio ambiente y fabricado con materiales reciclados.

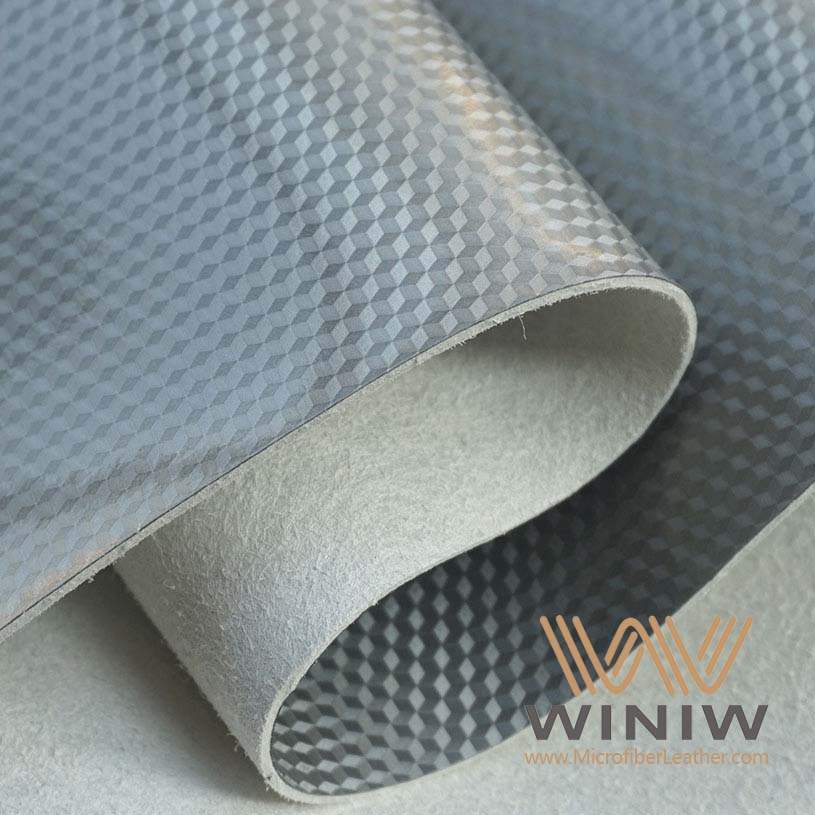

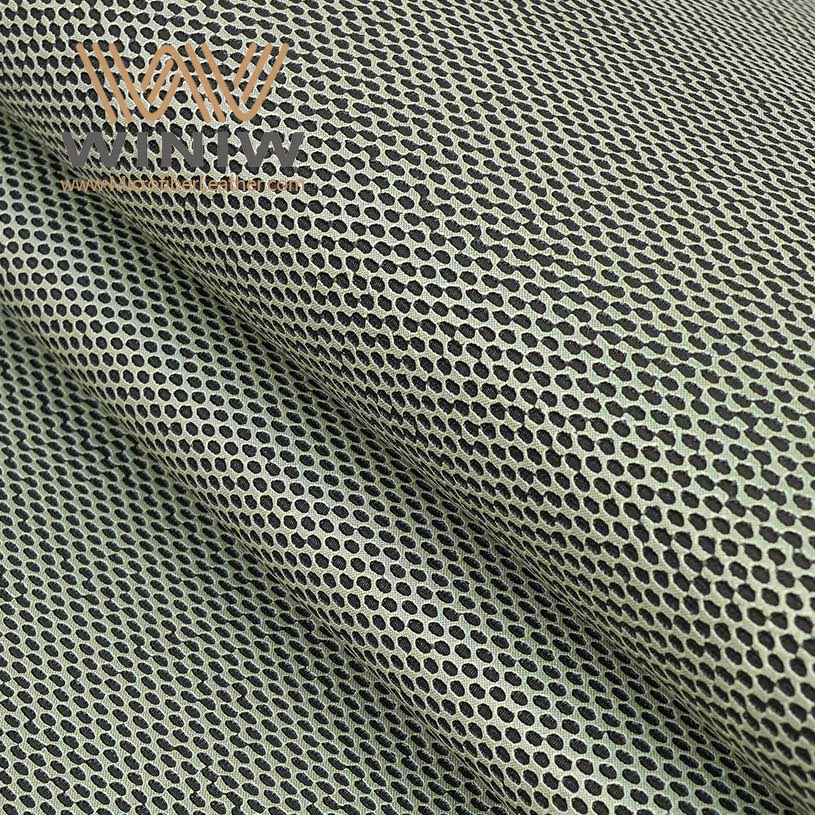

Microfibra :Imita la textura del cuero genuino, a menudo utilizado en productos de alta calidad.

|

Descripción |

|

|---|---|

|

Poliuretano a base de poliéster |

Un tipo de recubrimiento de PU derivado del poliéster, conocido por su flexibilidad y durabilidad. |

|

poliuretano a base de poliéter |

Derivado del poliéter, ofrece buena permeabilidad a la humedad y propiedades de ventilación del aire. |

|

Poliuretano a base de isocianato aromático |

Contiene isocianatos aromáticos, normalmente utilizados para aplicaciones específicas que requieren resistencia. |

|

Poliuretano a base de isocianato alifático |

Utiliza isocianatos alifáticos, a menudo elegidos para aplicaciones en exteriores debido a su mejor resistencia a la intemperie. |

|

Recubrimientos de PU a base de disolventes |

Recubrimientos tradicionales que utilizan solventes, a menudo con mayor rendimiento pero que plantean preocupaciones medioambientales. |

|

Recubrimientos de PU a base de agua |

Opciones más amigables con el medio ambiente que han ganado popularidad debido a las regulaciones. |

Consejo: Al seleccionar un tejido de PU, tenga en cuenta tanto el tipo de recubrimiento como el sustrato. Esta combinación determina la durabilidad, la comodidad y la idoneidad del tejido para el uso previsto.

Comienza seleccionando las materias primas adecuadas para Producción textil de PU La mayoría de los fabricantes utilizan poliuretano como polímero principal. Puede elegir entre poliuretano derivado del petróleo y alternativas de origen biológico. El poliuretano derivado del petróleo proviene de combustibles fósiles, mientras que las alternativas de origen biológico utilizan fuentes renovables de biomasa. La elección de la materia prima influye en la sostenibilidad y el impacto ambiental del producto final.

También se necesita un sustrato para el textil. Entre los sustratos más comunes se encuentran el poliéster, el nailon y el algodón. Estos tejidos base aportan estructura e influyen en la sensación y el rendimiento del material acabado. También se pueden encontrar sustratos de poliéster reciclado o microfibra, que ofrecen ventajas únicas para aplicaciones específicas.

Para crear textiles de PU, se siguen varios pasos clave. Cada paso garantiza que el producto final cumpla con sus requisitos de durabilidad, comodidad y apariencia.

Preparación de la tela Se estabiliza y limpia el tejido base antes de aplicar cualquier recubrimiento. Este paso garantiza que el sustrato esté listo para su posterior procesamiento.

Revestimiento Se aplican recubrimientos de poliuretano a la tela preparada. Los fabricantes utilizan técnicas como el recubrimiento con cuchilla, el curado en seco y la extrusión termofusible. Estos métodos permiten controlar el espesor y la uniformidad de los recubrimientos de poliuretano.

Laminado Se adhiere una película de poliuretano prefabricada al sustrato. Se pueden utilizar métodos térmicos o adhesivos para la laminación. Este paso mejora la resistencia y la impermeabilidad del tejido.

Técnicas utilizadas Se puede utilizar el recubrimiento de hilo, el recubrimiento extendido, la inmersión o el calandrado. En ocasiones, se combinan estas técnicas para lograr características de rendimiento específicas.

La base coagulada se crea sumergiendo el sustrato en una solución de poliuretano. Esta penetra en el tejido y forma una capa estable y flexible. A continuación, se utiliza un baño de coagulación para solidificar el poliuretano, obteniendo una base uniforme. Este proceso confiere al tejido su resistencia y flexibilidad fundamentales.

Se aplica una capa adhesiva para unir el revestimiento de poliuretano al sustrato. Esta capa garantiza que los revestimientos de PU se adhieran firmemente y no se despeguen ni se separen durante el uso. Se pueden utilizar adhesivos a base de agua o de disolventes, según el rendimiento y las necesidades ambientales.

El textil se remata con una capa superior decorativa. Esta capa proporciona el color, la textura y los efectos superficiales deseados. Puede elegir entre acabados brillantes, mate o en relieve. La capa superior también añade protección adicional contra la abrasión y la exposición a los rayos UV. Algunos fabricantes utilizan recubrimientos impermeables y permeables a la humedad para mejorar la transpirabilidad y la comodidad.

Puede elegir recubrimientos de poliuretano de base biológica para un opción más sostenible El poliuretano de origen biológico utiliza fuentes de biomasa renovables en lugar de combustibles fósiles. El proceso de producción puede incluir modificaciones funcionales para mejorar el rendimiento y la biodegradabilidad. Se beneficia de un menor impacto ambiental y una mayor sostenibilidad.

|

Aspecto |

PU a base de petróleo |

PU de base biológica |

|---|---|---|

|

Materias primas |

Derivado de combustibles fósiles |

Derivado de fuentes de biomasa renovables |

|

Impacto ambiental |

Contribuye a la contaminación y al agotamiento de los recursos. |

Más respetuoso con el medio ambiente, biodegradable. |

|

Sostenibilidad |

No renovable |

Renovable y sostenible |

|

Proceso de producción |

Procesos químicos tradicionales |

Utiliza biomasa y puede implicar modificaciones funcionales. |

Consejo: Al seleccionar textiles de PU, tenga en cuenta el tipo de revestimiento de poliuretano y el sustrato. Puede optar por PU de origen biológico para una solución más ecológica.

Confía en el PU cuando necesita un material resistente al desgaste diario. Los fabricantes diseñan el PU para que sea especialmente duradero, lo que lo convierte en la mejor opción para artículos de uso intensivo como muebles, asientos de coche y bolsos. A diferencia de muchas fibras naturales, que tienden a degradarse más rápido, el PU mantiene su integridad con el tiempo. Observará que el PU suele superar a otras pieles sintéticas en cuanto a resistencia al agrietamiento y al desprendimiento. Esta durabilidad lo hace adecuado para entornos de uso frecuente y exposición a altas tensiones.

El cuero PU es reconocido por su durabilidad y resistencia al desgaste, lo que lo hace ideal para uso intensivo.

Las fibras naturales generalmente tienen una vida útil más corta en comparación con los materiales sintéticos.

Si bien el cuero PU supera a algunos cueros sintéticos en durabilidad, tiene limitaciones en cuanto a transpirabilidad y posibles preocupaciones ambientales.

Consejo: Si desea un producto duradero, elija tejido PU por su probada durabilidad y capacidad de soportar el uso repetido.

Se beneficia de la impresionante resistencia al agua de los textiles de PU, especialmente en productos diseñados para exteriores o entornos húmedos. Los fabricantes prueban los tejidos de PU en condiciones estandarizadas para garantizar que cumplan con altos índices de columna de agua. Esto significa que el tejido permanece impermeable incluso expuesto a humedad o presión considerables, como en tiendas de campaña o ropa impermeable. Los recubrimientos de PU crean una barrera que impide que el agua penetre en la superficie, manteniéndole seco y cómodo.

Los textiles de PU alcanzan una resistencia a la hidrólisis de hasta 16 semanas, superando el estándar de la industria de 5 semanas. La carga hidrostática suele superar los 10 000 mm, lo que confirma la idoneidad del material para aplicaciones exigentes.

|

Métrico |

Rendimiento textil de PU |

|---|---|

|

Resistencia a la hidrólisis |

16 semanas (por encima del estándar de la industria de 5 semanas) |

|

Clasificación de la carga hidrostática |

Supera los 10.000 mm |

Debe saber que los recubrimientos de PU son hidrófilos, por lo que pueden absorber agua con el tiempo. Si bien los textiles de PU inicialmente resisten la penetración del agua, la exposición prolongada puede provocar saturación y fugas. Para la mayoría de los usos cotidianos, los textiles de PU son impermeables y confiables.

Los recubrimientos de PU son hidrófilos, lo que significa que pueden absorber agua con el tiempo.

Si bien inicialmente resisten la penetración de agua, la exposición prolongada puede provocar saturación y fugas.

Nota: Para equipos de exterior y ropa impermeable, el tejido de PU ofrece un equilibrio entre resistencia al agua y comodidad transpirable, lo que lo convierte en la opción preferida.

Aprecias la flexibilidad del PU, especialmente al compararlo con otros materiales sintéticos como el PVC. El cuero PU es más suave y flexible, lo que permite usarlo en productos que requieren movimiento y comodidad. La textura natural del PU se asemeja al cuero genuino, brindándote una apariencia y sensación premium sin sacrificar el rendimiento.

|

Material |

Blandura |

Flexibilidad |

|---|---|---|

|

PU |

Más suave |

Más flexible |

|

CLORURO DE POLIVINILO |

Más rígido |

Menos flexible |

|

Material |

Textura |

Flexibilidad |

|---|---|---|

|

PU |

Natural |

Más flexible |

|

CLORURO DE POLIVINILO |

Menos natural |

Menos flexible |

El cuero PU tiene una textura más natural que se asemeja al cuero genuino.

El PU es más suave y flexible en comparación con Cuero de PVC .

El cuero PU es más suave y flexible que el cuero PVC.

El cuero de PVC tiene una sensación más rígida y menos natural.

El tejido de PU se adapta bien a diferentes formas y usos, lo que lo hace ideal para ropa, accesorios y tapicería. Su flexibilidad también contribuye a su transpirabilidad, mejorando la comodidad al usarlo.

Consejo: cuando necesitas un material que se mueva contigo y sea cómodo, el tejido de PU ofrece una flexibilidad superior y una experiencia transpirable.

Se espera que los textiles modernos brinden comodidad, especialmente al usarlos durante períodos prolongados. La transpirabilidad es una propiedad crucial en los textiles de PU. Los fabricantes diseñan recubrimientos de PU para equilibrar la protección y la ventilación. Se observa que el tejido de PU transpirable permite que el aire y la humedad circulen a través del material, lo que ayuda a regular la temperatura y previene el sobrecalentamiento.

La permeabilidad a la humedad mide la capacidad de un tejido para absorber el vapor de agua. Una alta permeabilidad a la humedad se beneficia porque reduce la acumulación de sudor y te mantiene seco. Los tejidos de PU logran esto mediante estructuras microporosas o recubrimientos hidrófilos. Estas características permiten que el tejido absorba la humedad de la piel, manteniendo al mismo tiempo la resistencia al agua. Esta combinación es esencial en ropa deportiva, impermeables y equipamiento para actividades al aire libre.

Quizás se pregunte cómo se comparan los textiles de PU con otros materiales en términos de transpirabilidad. La siguiente tabla destaca las diferencias clave:

|

Material |

Transpirabilidad |

Permeabilidad a la humedad |

Resistencia al desgaste |

|---|---|---|---|

|

Textil de PU |

Moderado a alto |

Alto |

Alto |

|

Textil de PVC |

Bajo |

Bajo |

Moderado |

|

Piel genuina |

Moderado |

Moderado |

Alto |

Como puede ver, los textiles de PU ofrecen un excelente equilibrio entre permeabilidad a la humedad y resistencia al desgaste. Los fabricantes optimizan el grosor y la composición de los recubrimientos de PU para mejorar la ventilación sin sacrificar la durabilidad. Experimentará comodidad con las prendas de PU porque el tejido se adapta a su nivel de actividad y entorno.

Consejo: Al elegir textiles de PU para deportes o uso en exteriores, consulte las especificaciones del producto para conocer su índice de permeabilidad a la humedad. Un índice más alto indica mayor transpirabilidad y comodidad.

También se encuentran textiles de PU en tapicería e interiores de automóviles. La transpirabilidad es importante en estas aplicaciones, ya que previene la acumulación de calor y mejora la experiencia del usuario. Se observa que el tejido de PU transpirable se siente más fresco y cómodo, especialmente en climas cálidos.

Los fabricantes siguen innovando mediante el desarrollo de recubrimientos de PU avanzados con mayor permeabilidad a la humedad. Usted se beneficia de estos avances, ya que crean textiles que funcionan bien tanto en condiciones húmedas como secas. Disfruta de la versatilidad de los textiles de PU, sabiendo que ofrecen una resistencia al desgaste fiable y comodidad en una amplia gama de usos.

Nota: La transpirabilidad no implica sacrificar la protección. Los tejidos de PU mantienen la resistencia al agua y permiten la salida del vapor de humedad, lo que los hace ideales para entornos exigentes.

Obtendrá varias ventajas al elegir textiles de PU para sus proyectos. Los recubrimientos de poliuretano crean una capa protectora resistente al agua y al desgaste. Esta característica convierte al PU en una excelente opción para bolsos, zapatos y chaquetas. Observará que los textiles de PU conservan el aspecto natural del cuero y mejoran su rendimiento. Los fabricantes aplican el poliuretano en forma líquida, lo que permite que la tela conserve su flexibilidad y comodidad.

Los textiles de PU destacan por su durabilidad. Confía en ellos para equipos de exterior y aplicaciones industriales, ya que resisten el uso frecuente y las condiciones más adversas. La resistencia al agua de los recubrimientos de PU impide que la humedad penetre en el tejido, lo cual es crucial para la ropa impermeable y de protección. También se beneficia de la flexibilidad de los textiles de PU. A diferencia de otros recubrimientos, el PU no endurece el tejido. Disfruta de comodidad y libertad de movimiento en ropa deportiva y artículos de moda.

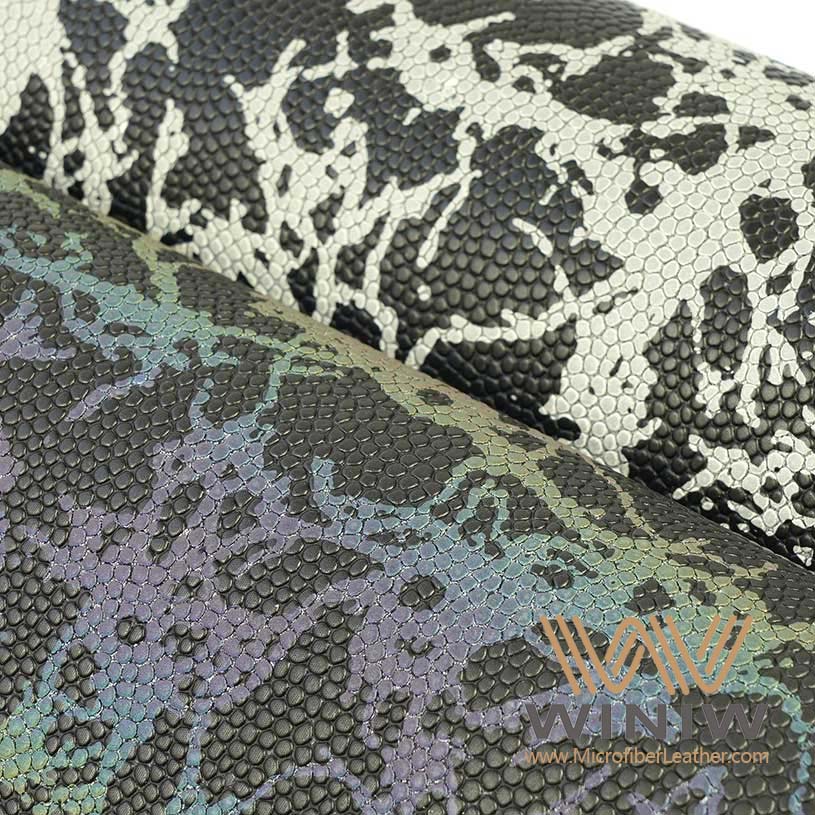

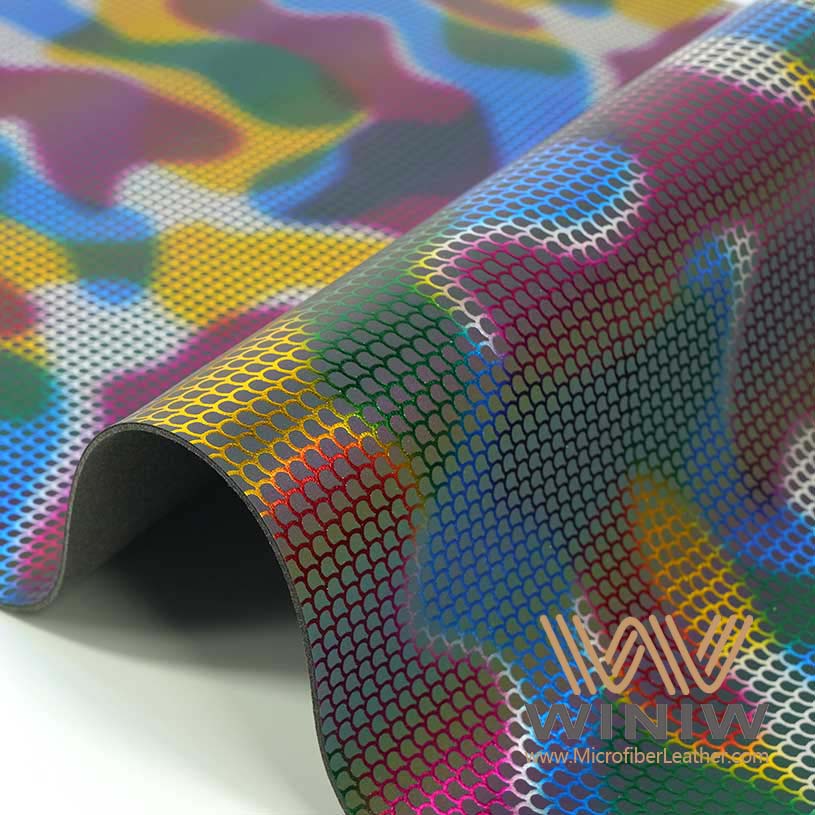

El atractivo estético de los textiles de PU ofrece opciones creativas. Puede elegir acabados que van desde mate hasta brillante, lo que le permite diseñar productos que se adapten a su estilo. Los fabricantes valoran la adaptabilidad del PU en la producción. Su proceso de aplicación se adapta a diversos métodos de fabricación, lo que lo convierte en una opción práctica para operaciones a gran escala.

|

Beneficio |

Descripción |

|---|---|

|

Durabilidad |

Los textiles de PU ofrecen una durabilidad excepcional, formando una sólida capa protectora que aumenta la resistencia al desgaste. Ideales para equipos de exterior y textiles industriales. |

|

Resistencia al agua |

Los recubrimientos de PU proporcionan una excelente resistencia al agua, evitando que la humedad penetre en el tejido, algo crucial para los textiles de exterior. |

|

Flexibilidad |

A diferencia de otros recubrimientos, el PU mantiene la caída natural y la flexibilidad de los tejidos, esenciales para la comodidad en la ropa deportiva y los textiles de moda. |

|

Mejora estética |

Los recubrimientos de PU pueden mejorar el atractivo visual de las telas, disponibles en varios acabados, desde mate hasta brillante, lo que permite diseños creativos. |

|

Adaptabilidad en la producción |

El proceso de aplicación de recubrimientos de PU es sencillo y se puede adaptar a diversos métodos de producción, lo que lo convierte en una opción viable para los fabricantes. |

Puedes ver estos beneficios reflejados en muchos productos:

Durabilidad :Aumenta la resistencia al desgaste, ideal para artículos de uso frecuente.

Resistencia al agua :Evita la penetración de humedad, mejorando la impermeabilidad.

Flexibilidad :Mantiene la caída natural y la comodidad de las telas.

Atractivo estético :Disponible en varios acabados para diseños creativos.

Adaptabilidad de la producción :Fácil de integrar en los procesos de fabricación existentes.

Consejo: Si buscas textiles que combinen rendimiento y estilo, el PU ofrece una solución confiable tanto para las necesidades industriales como de moda.

Debe considerar las desventajas antes de seleccionar textiles de PU para su aplicación. Los materiales de PU, si bien son duraderos, en algunos casos pueden no igualar la longevidad del cuero genuino. Es posible que note que el PU puede degradarse con el tiempo, especialmente al exponerse a la luz solar o a una humedad alta. La superficie puede agrietarse o descascarillarse si no se mantiene adecuadamente.

La transpirabilidad presenta otro desafío. Si bien los textiles de PU ofrecen una ventilación moderada, no alcanzan el mismo nivel que las fibras naturales. Podría experimentar incomodidad en ambientes cálidos o húmedos si el tejido retiene el calor y la humedad. Algunos recubrimientos de PU absorben agua con el tiempo, lo que puede reducir su eficacia en condiciones de humedad prolongada.

El impacto ambiental sigue siendo preocupante. La mayoría de los textiles de PU utilizan poliuretano derivado del petróleo, lo que contribuye al agotamiento de los recursos y a la contaminación. Las opciones de reciclaje para los materiales de PU son limitadas, y su eliminación puede generar problemas de gestión de residuos. Existen alternativas de PU de origen biológico, pero son menos comunes y pueden ser más costosas.

|

Inconveniente |

Descripción |

|---|---|

|

Longevidad limitada |

El PU puede agrietarse o pelarse con el tiempo, especialmente en condiciones adversas. |

|

Transpirabilidad moderada |

Los textiles de PU no ofrecen el mismo flujo de aire que las fibras naturales, lo que puede afectar la comodidad. |

|

El PU derivado del petróleo contribuye a la contaminación y al agotamiento de los recursos; las opciones de reciclaje son limitadas. |

|

|

Necesidades de mantenimiento |

El PU requiere un cuidado regular para evitar daños en la superficie y mantener la apariencia. |

Nota: Debe sopesar las ventajas y desventajas para determinar si el tejido de PU satisface sus necesidades específicas. Considere factores como la durabilidad, la comodidad y la sostenibilidad antes de tomar una decisión.

A menudo se comparan los textiles de PU y el PVC al elegir materiales para tapicería, equipo para actividades al aire libre o accesorios de moda. El PVC atrae a los compradores por su... menor costo inicial Ahorra dinero al principio, pero podría enfrentar mayores gastos más adelante, ya que el PVC tiende a degradarse y requiere reemplazo frecuente. Los textiles de PU, aunque más caros al principio, ofrecen mayor durabilidad. El costo total de propiedad podría ser menor con el PU debido a su durabilidad.

|

Aspecto |

CLORURO DE POLIVINILO |

Textil de PU |

|---|---|---|

|

Costo |

Producción económica, ahorro a largo plazo |

Costos iniciales generalmente más altos |

|

Impacto ambiental |

Criticado por posibles daños, pero existen mejoras en el reciclaje |

Se considera más ecológico, pero el reciclaje puede consumir mucha energía. |

Debe considerar el impacto ambiental al tomar su decisión. Los textiles de PU son generalmente... más ecológico que el PVC El PU ofrece mayor reciclabilidad y menor toxicidad. La producción de PVC genera subproductos nocivos y es menos reciclable, lo que genera inquietudes sobre la sostenibilidad.

El PVC proporciona Resistente a la intemperie y protección UV eficaz Quizás prefiera el PVC para aplicaciones exteriores.

Los textiles de PU ofrecen mayor flexibilidad y resistencia. El PU se beneficia de su uso en productos que requieren alta durabilidad y comodidad.

Consejo: Si prioriza el respeto al medio ambiente y el rendimiento a largo plazo, los textiles de PU son una mejor opción. Para proyectos a corto plazo y con un presupuesto ajustado, el PVC podría ser la solución ideal.

Te encuentras con Cuero de PU y cuero genuino en moda, muebles e interiores de automóviles. Las diferencias entre estos materiales influyen en su decisión de compra.

|

Característica |

Piel genuina |

Cuero de PU |

|---|---|---|

|

Material |

Hecho de pieles naturales de animales. |

Fabricado con materiales sintéticos |

|

Durabilidad |

Altamente duradero y de larga duración. |

Menos duradero, puede agrietarse o pelarse. |

|

Apariencia |

Textura natural, única, desarrolla pátina. |

Apariencia más uniforme, textura suave. |

|

Mantenimiento |

Requiere acondicionamiento regular |

Más fácil de limpiar y mantener. |

Apariencia El cuero genuino le brinda una textura única y una sensación de lujo. El cuero PU imita diversos materiales, pero suele tener un aspecto más uniforme.

Durabilidad Confía en el cuero genuino para un uso duradero. El cuero PU puede perforarse o romperse con mayor facilidad.

Mantenimiento Es necesario acondicionar el cuero genuino con regularidad para evitar que se seque y se agriete. El cuero sintético requiere menos mantenimiento y es más fácil de limpiar.

Nota: Si busca una apariencia premium y máxima durabilidad, el cuero genuino es la mejor opción. Por su fácil mantenimiento y precio accesible, el cuero PU ofrece ventajas prácticas.

Puede considerar los textiles de silicona para aplicaciones especializadas, especialmente donde la flexibilidad y la resistencia al calor son importantes. Los textiles de PU pueden diseñarse para ofrecer flexibilidad o rigidez, según sus necesidades. Los textiles de silicona ofrecen alta elasticidad y durabilidad, lo que los hace ideales para productos que requieren movimiento frecuente.

|

Propiedad |

Textiles de PU |

Textiles de silicona |

|---|---|---|

|

Flexibilidad |

Puede ser Diseñado para flexibilidad o rigidez . |

Alta elasticidad y durabilidad, ideal para el movimiento. |

|

Resistencia al calor |

Varía según la formulación; algunos resisten el calor, otros no. |

Excelente resistencia al calor, no sujeto a degradación en ambientes críticos. |

Observa que los textiles de silicona destacan en entornos con altas temperaturas. Los textiles de PU pueden resistir el calor, pero su rendimiento depende de la formulación específica. La silicona no se degrada en condiciones críticas, por lo que la elige para usos industriales o médicos.

Los textiles de PU ofrecen versatilidad en moda y tapicería.

Los textiles de silicona proporcionan un rendimiento superior en entornos exigentes y de alto calor.

Consejo: Elija tejidos de PU para una flexibilidad y comodidad óptimas. Elija tejidos de silicona si necesita resistencia al calor y elasticidad excepcionales.

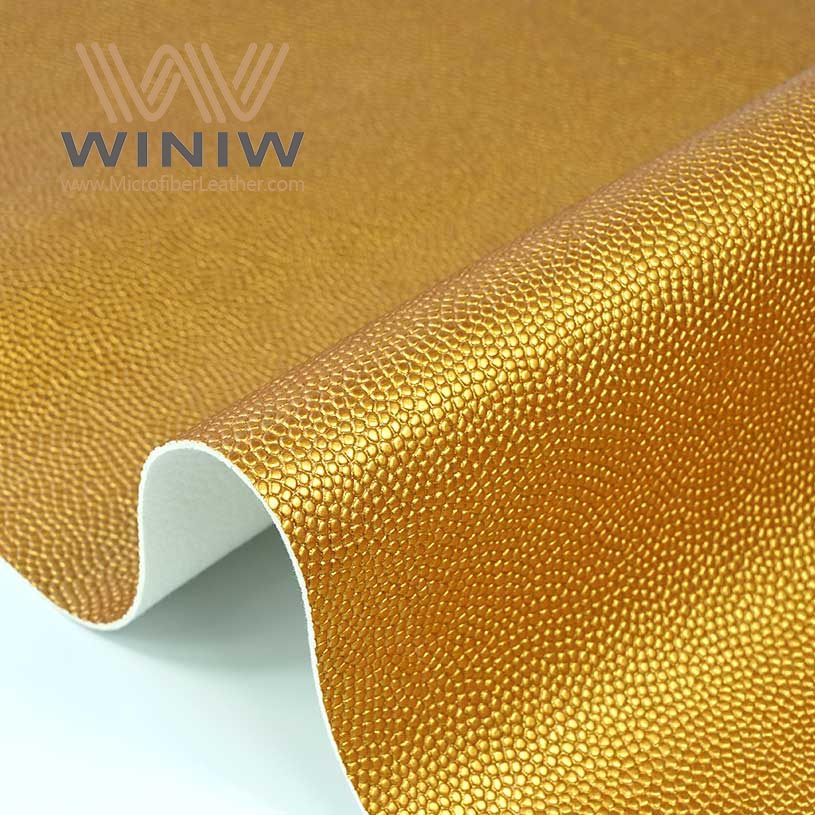

El PU es un material muy común en la industria de la moda. Los diseñadores lo eligen por su versatilidad y precio asequible. Se puede encontrar PU en chaquetas, zapatos, bolsos y accesorios. Muchas marcas lo utilizan como... Alternativa rentable al cuero genuino Te beneficias de su durabilidad y fácil limpieza, lo que lo hace perfecto para los artículos que usas a diario.

El tejido de PU te da un toque elegante. Mira sin el alto precio del cuero real.

Disfruta de productos que duran más y resisten las manchas.

El material se adapta a muchos estilos, desde el clásico hasta el más actual.

Observarás más marcas, como Xinchunlan, que ofrecen productos de PU modernos y asequibles.

El cambio hacia materiales sustentables impulsa la adopción de PU, ya que usted y otros consumidores buscan opciones ecológicas.

Consejo: Si quieres seguir las últimas tendencias de la moda y apoyar la sostenibilidad, elige ropa y accesorios a base de PU.

El PU se utiliza en muebles y diseño de interiores. Los fabricantes utilizan cuero PU para sofás, sillas y cojines. Al elegir PU para tapicería, se obtienen varias ventajas.

La durabilidad se destaca El cuero PU resiste el desgaste, por lo que sus muebles lucirán nuevos por más tiempo.

La rentabilidad es importante. Pagas menos por piezas elegantes que por opciones de cuero genuino.

El respeto al medio ambiente te atrae. El cuero sintético evita el uso de productos animales y puede utilizar soluciones a base de agua, lo que reduce las emisiones nocivas.

El mantenimiento sencillo le ahorra tiempo. Las superficies de PU se limpian rápidamente y conservan su aspecto sin mucho esfuerzo.

Su versatilidad te permite elegir entre una gran variedad de texturas, colores y acabados. Incluso puedes encontrar cuero sintético que imita patrones exóticos.

Creas un espacio cómodo y atractivo con tapicería de PU. Además, apoyas prácticas éticas y sostenibles.

Nota: Si desea muebles que combinen estilo, durabilidad y fácil cuidado, el textil PU ofrece una solución inteligente.

Confías en el tejido de PU para tu equipo de exterior porque rinde bien en condiciones difíciles. Los fabricantes utilizan revestimientos de PU en impermeables, tiendas de campaña, mochilas y ropa de protección. Te beneficias de varias propiedades clave:

|

Propiedad |

Descripción |

|---|---|

|

Durabilidad |

Alta resistencia a la tracción y al rayado y al desgarro. |

|

El revestimiento de PU actúa como una barrera contra la humedad, mejorando la resistencia al agua. |

|

|

Transpirabilidad |

Permite que la humedad escape mientras evita la penetración de agua. |

Manténgase seco y cómodo durante las actividades al aire libre. El tejido de PU mantiene su equipo ligero y flexible, permitiéndole moverse con libertad. Además, el PU mantiene su rendimiento en condiciones climáticas extremas, lo que lo convierte en una opción confiable para senderismo, acampada y deportes.

Consejo: Cuando compre equipo para actividades al aire libre, busque telas recubiertas de PU para garantizar protección y comodidad en cualquier entorno.

Te encuentras con Textiles de PU en toda la industria automotriz Industria. Los fabricantes confían en telas recubiertas de poliuretano y cuero de PU para crear interiores que equilibran durabilidad, comodidad y estilo. Al entrar en un vehículo moderno, se observa que los asientos, el tablero, los paneles de las puertas y las cubiertas del volante suelen estar fabricados con materiales de PU. Estos componentes deben soportar el uso constante, la exposición a la luz solar y las fluctuaciones de temperatura. Los textiles de PU ofrecen la resistencia y el atractivo estético que exigen los diseñadores de automóviles.

El cuero PU en los asientos de coche se beneficia de su resistencia a las manchas y la abrasión. La limpieza es sencilla y mantiene un aspecto impecable con un mínimo esfuerzo. A diferencia del cuero genuino, el PU no requiere un acondicionamiento regular. Evita el agrietamiento y la decoloración, incluso después de años de uso. La flexibilidad del PU permite a los fabricantes moldearlo en formas ergonómicas, mejorando la comodidad de conductores y pasajeros.

Las aplicaciones automotrices exigen estrictos estándares de seguridad y rendimiento. Los textiles de PU cumplen con estos requisitos al ofrecer resistencia al fuego y bajas emisiones. Experimentará una mejor calidad del aire en su vehículo gracias a que los materiales de PU liberan menos compuestos orgánicos volátiles (COV) que otras alternativas. Esta característica contribuye a un ambiente más saludable para usted y sus pasajeros.

Consejo: Al elegir un vehículo, revise las especificaciones interiores. La tapicería de PU suele ofrecer un equilibrio entre lujo y practicidad a un precio menor que el cuero genuino.

También se ven textiles de PU en tapizados de techo, parasoles y revestimientos de maletero. Estos componentes requieren materiales ligeros y flexibles que mantengan su forma con el tiempo. Los recubrimientos de PU protegen las superficies de la humedad y los rayos UV, lo que prolonga la vida útil del interior del coche.

A continuación se muestra una comparación de los textiles de PU con otros materiales automotrices comunes:

|

Característica |

Textil de PU |

Piel genuina |

CLORURO DE POLIVINILO |

|---|---|---|---|

|

Durabilidad |

Alto |

Muy alto |

Mode

Casa

| Aplicaciones

| Acerca de nosotros

| Noticias

| Póngase en contacto con nosotros

| Videos

| Blog

| Sitemap

| XML

| Política De Privacidad

Derechos de autor © Winiw International Co.,Ltd Todos los derechos reservados

IPv6 red compatible

|