Para trabajos exigentes, muchos profesionales eligen guantes de trabajo de cuero por su probada durabilidad y gran protección contra riesgos. Elegir entre guantes de trabajo de cuero y sintéticos es fundamental para la seguridad, ya que la elección correcta puede ayudar a prevenir laceraciones, aplastamientos e impactos severos. La siguiente tabla muestra cómo los guantes reducen el riesgo de lesiones comunes en las manos en el trabajo:

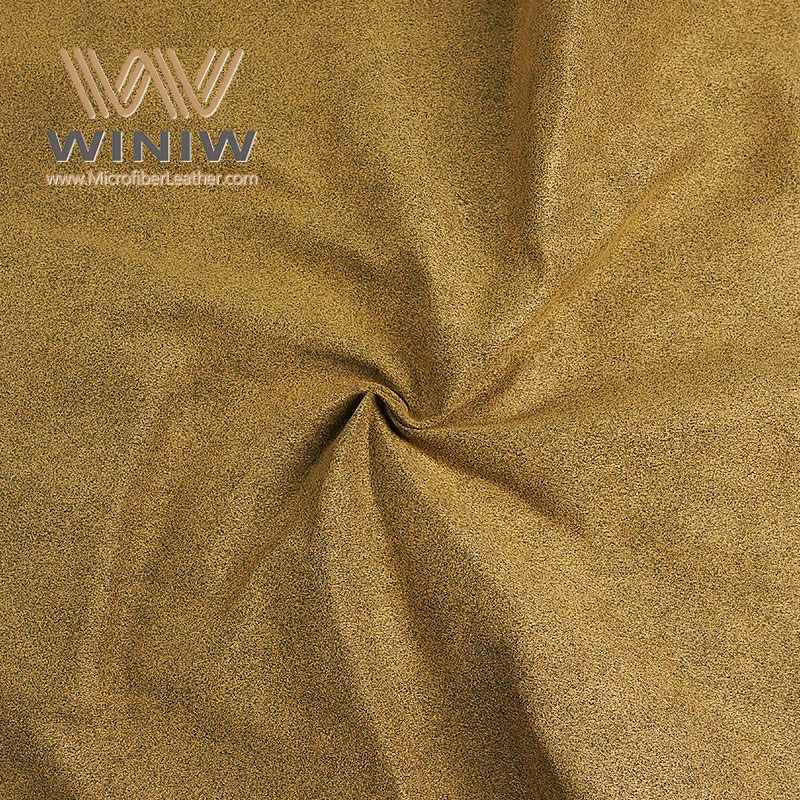

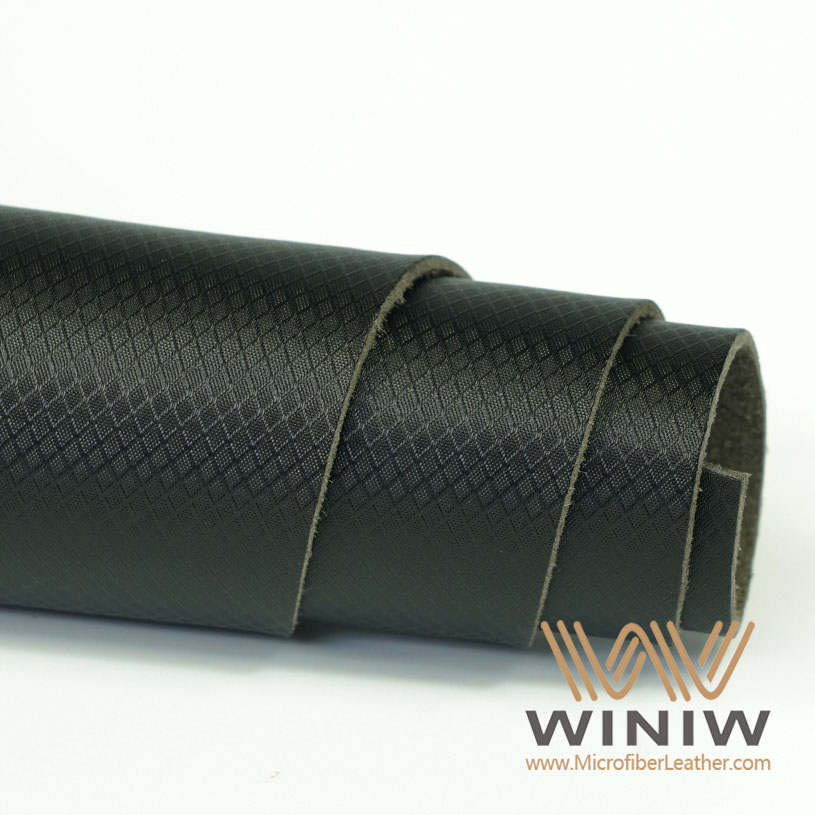

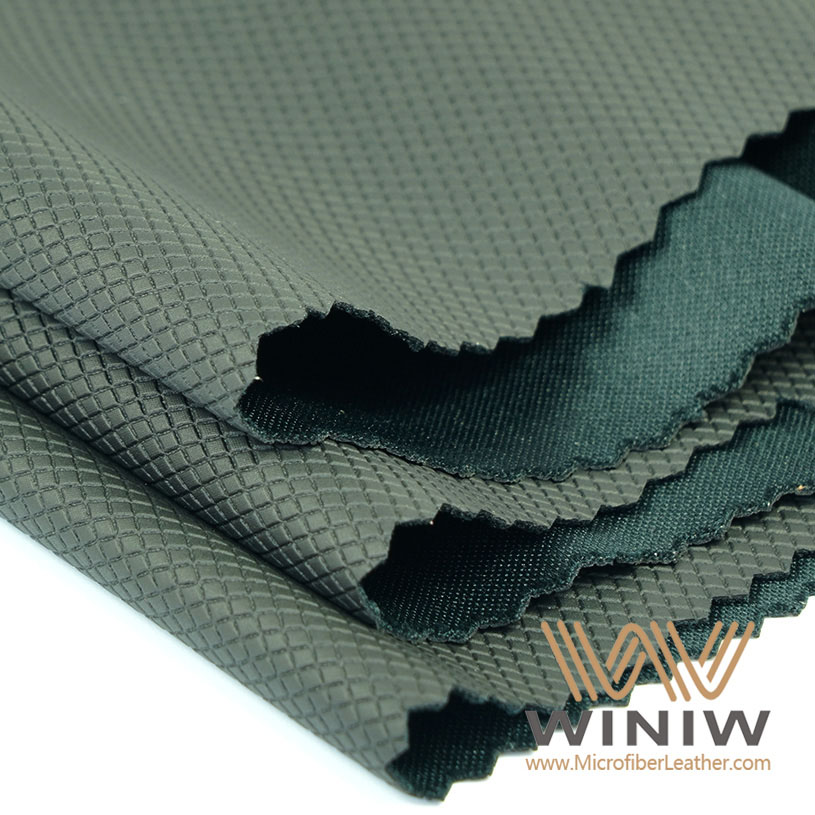

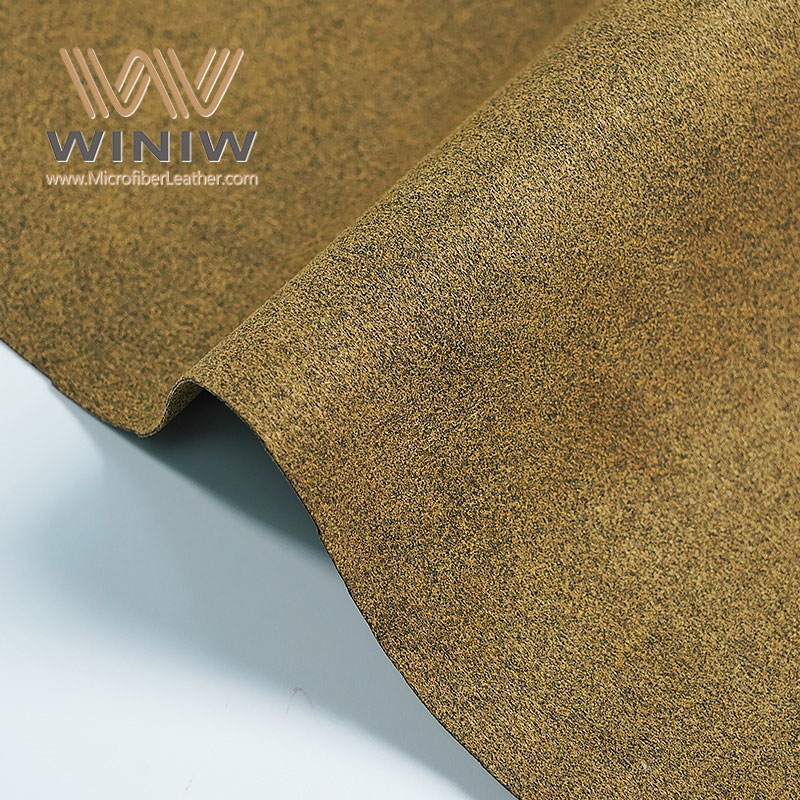

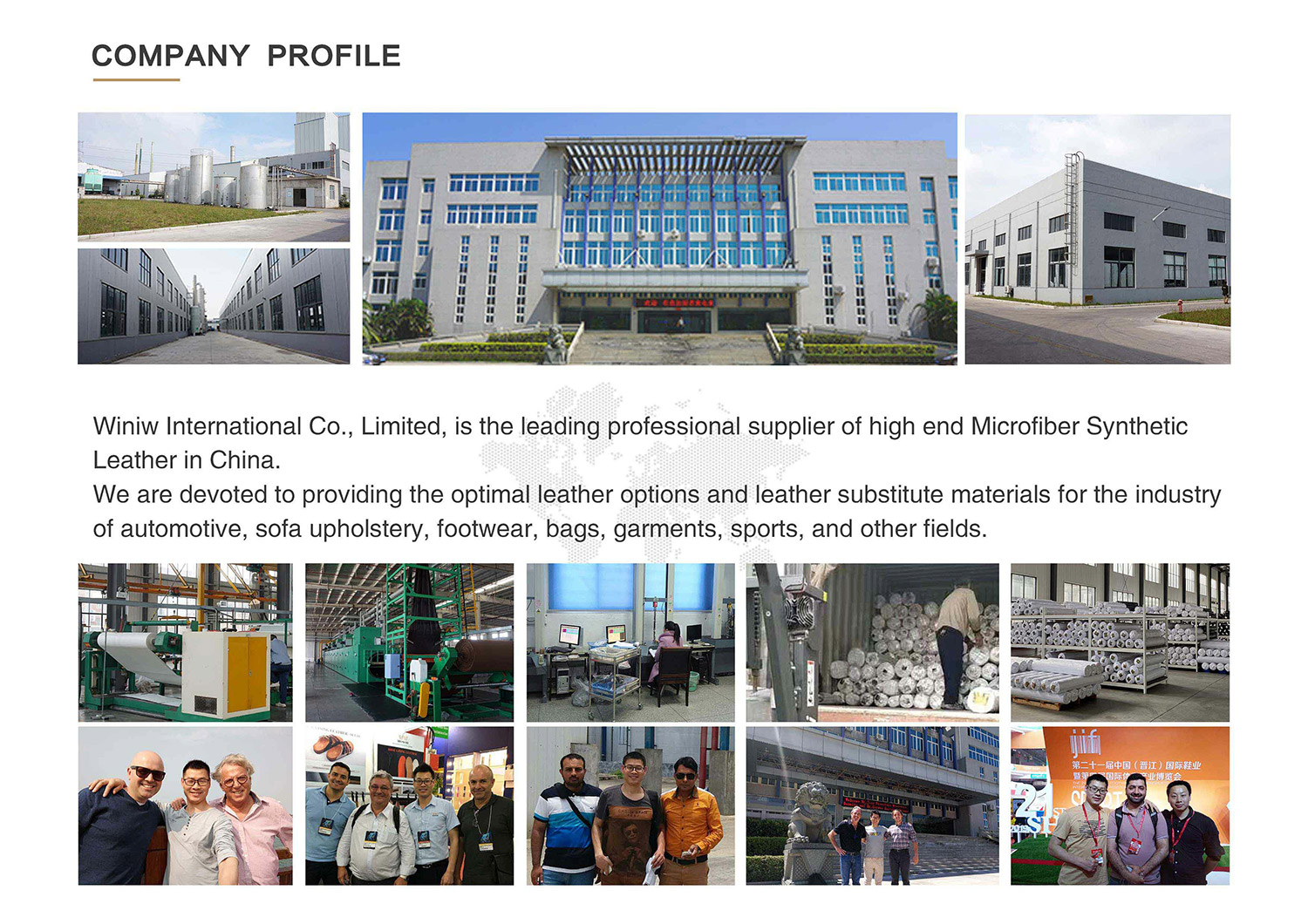

Cueros sintéticos y cuero vegano Ahora ofrecemos alternativas innovadoras y sostenibles. Los trabajadores deben considerar sus tareas, su comodidad y su valor ambiental antes de tomar una decisión.

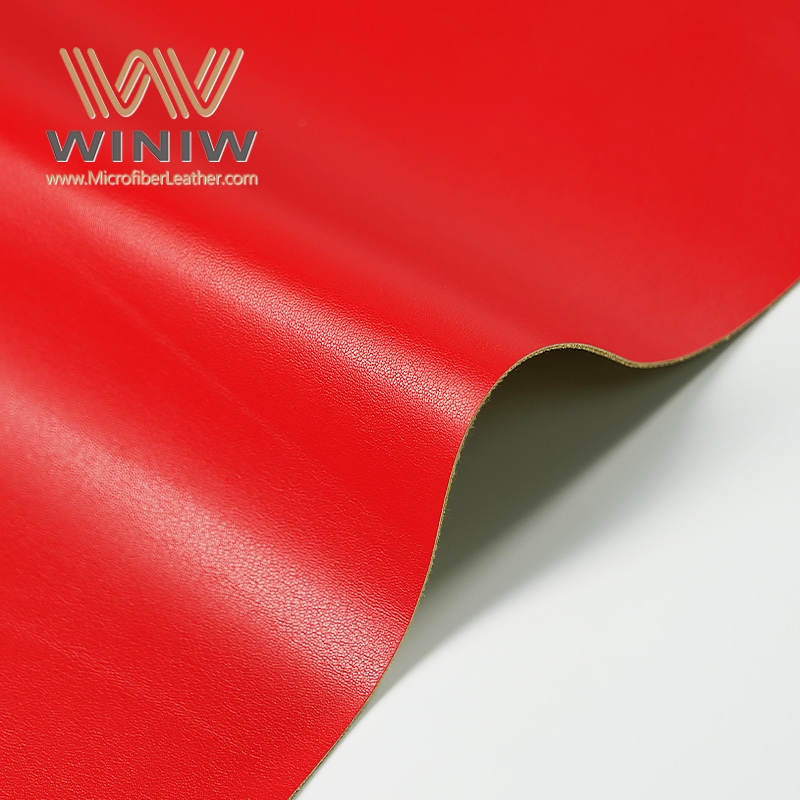

Los guantes de cuero se destacan por su durabilidad y resistencia a la abrasión, lo que los hace ideales para tareas pesadas como soldadura y construcción.

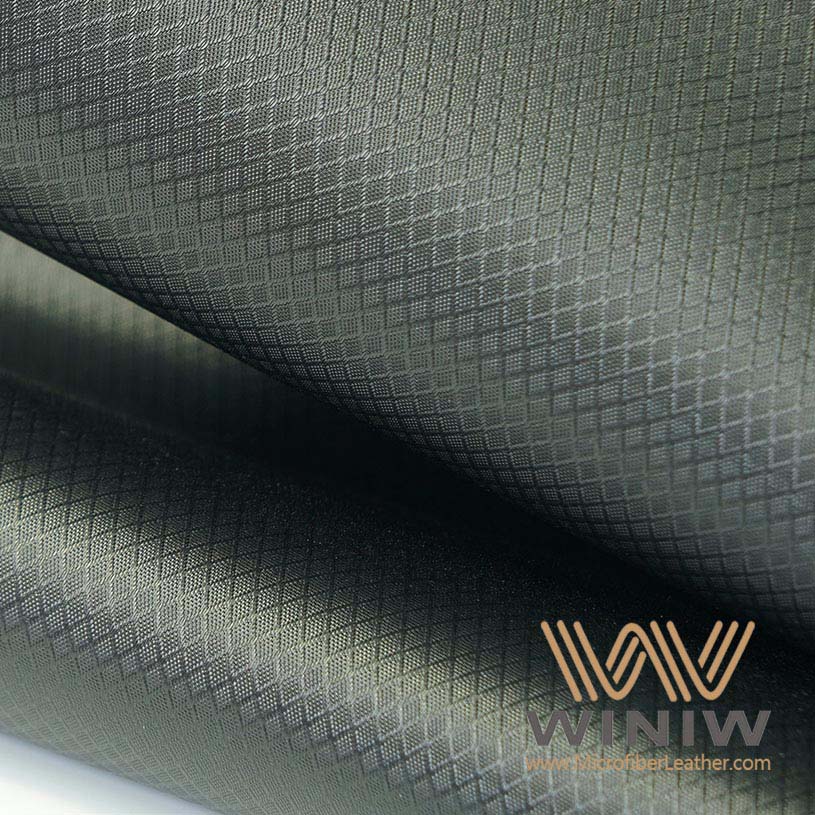

Los guantes sintéticos ofrecen una resistencia al corte y una flexibilidad superiores, lo que los hace adecuados para trabajos que requieren gran destreza y exposición a productos químicos.

Tenga en cuenta los requisitos específicos del trabajo al elegir los guantes; el cuero es mejor para el calor y la abrasión, mientras que el sintético es mejor para la protección química.

Guantes de cuero vegano Ofrecer una alternativa ecológica, utilizando materiales de origen vegetal que reducen la dependencia de productos animales.

Un mantenimiento adecuado prolonga la vida útil de los guantes; límpielos y séquelos al aire regularmente para evitar el desgaste.

La transpirabilidad es clave para la comodidad; elija guantes con materiales que permitan el flujo de aire para mantener las manos frescas durante turnos largos.

Verifique siempre el cumplimiento de las normas de seguridad para garantizar que los guantes brinden protección adecuada contra cortes, abrasiones y productos químicos.

Invierta en guantes que equilibren protección, comodidad y sostenibilidad para mejorar la seguridad y el rendimiento en el trabajo.

Los profesionales suelen debatir las ventajas de los guantes de trabajo de cuero y sintéticos al seleccionar el equipo para tareas exigentes. Cada tipo ofrece ventajas y limitaciones distintas. La siguiente tabla presenta una comparación de las métricas clave de rendimiento para trabajos exigentes:

|

Tipo de guante |

Métricas clave de rendimiento |

|---|---|

|

Guantes de trabajo de cuero |

Durabilidad, resistencia a la abrasión, protección contra el calor. |

|

|

Ideal para tareas pesadas como soldadura y manipulación de materiales. |

|

Guantes sintéticos |

Resistencia superior al corte, flexibilidad y protección química. |

|

|

Ideal para tareas que requieren gran destreza y entornos húmedos. |

Los guantes de trabajo de cuero destacan por su durabilidad y resistencia a la abrasión. Protegen las manos del calor y las superficies rugosas, lo que los hace ideales para trabajos como soldadura y construcción. Los guantes sintéticos ofrecen mayor resistencia al corte y flexibilidad. Son eficaces en entornos con presencia de productos químicos o humedad. Los trabajadores que requieren gran destreza suelen preferir las opciones sintéticas.

El costo también influye en la elección del tipo adecuado de guantes de trabajo. La siguiente tabla muestra los precios típicos de los modelos más populares:

|

Tipo de guante |

Precio |

|---|---|

|

Guante multiactividad Caiman® MAG™ |

$30.24 |

|

Guantes de mecánico con armadura (caja de 12) |

$122.95 - $129.10 |

|

Guantes de piel de vaca |

$2.82 |

|

Guante de mecánico de piel de armadura |

$21.42 |

|

Guantes con palma de cuero Pyramex serie GL104HT |

$12.62 |

Los guantes de piel de vacuno ofrecen una opción económica para una protección básica. Los guantes sintéticos, especialmente los diseñados para mecánicos, pueden ser más caros, pero ofrecen características especializadas.

Los guantes de trabajo de cuero y los sintéticos se diferencian en varios aspectos importantes. Los guantes de cuero tienen fama de ser más duraderos y cómodos. Son resistentes a los productos químicos, al calor y al agua, lo que aumenta su durabilidad. Por ejemplo, los guantes Wells Lamont HydraHyde se mantienen cómodos y eficaces incluso en condiciones de humedad. Los guantes sintéticos, aunque más fáciles de mantener y económicos, no transpiran tan bien y pueden no durar tanto como los de cuero genuino.

Nota: Cuero artificial Es más fino, flexible y lavable que el cuero auténtico. No se estira ni respira como el cuero genuino. El cuero auténtico requiere acondicionamiento para mantener su flexibilidad, mientras que el cuero artificial no se endurece al secarse.

La sostenibilidad se ha convertido en un factor importante en la selección de guantes. Pieles sintéticas y cuero vegano Las alternativas ofrecen opciones ecológicas para quienes valoran la responsabilidad ambiental. La siguiente tabla destaca las ventajas y desventajas de cada material en términos de sostenibilidad:

|

Tipo de material |

Profesionales de la sostenibilidad |

Desventajas de la sostenibilidad |

|---|---|---|

|

Cuero vegano |

No contiene subproductos animales; mejor que el cuero real. |

La producción de plásticos no es respetuosa con el medio ambiente; a menudo se fabrican a partir de plástico (combustibles fósiles). |

|

cuero de imitación (PU) |

Menores emisiones de carbono en comparación con el cuero. |

Hecho de plástico; puede tardar cientos de años en descomponerse; genera más desechos debido a su menor durabilidad |

|

Durable y de larga duración |

Mayores emisiones de carbono; implica subproductos animales |

Cueros sintéticos cuero vegano Destaca por el uso de materiales vegetales, como piña, cactus y uva. Estas alternativas reducen la dependencia de productos animales y las emisiones de carbono. Los trabajadores que priorizan la sostenibilidad pueden optar por guantes de cuero vegano o de piel sintética por sus beneficios ecológicos.

Los guantes de cuero vienen en varios tipos, cada uno con cualidades únicas. El cuero flor aprovecha toda la capa de flor, lo que lo convierte en el más resistente y duradero. El serraje proviene de las capas inferiores de la piel y ofrece flexibilidad a un menor costo. La elección entre cuero flor y serraje influye en el rendimiento y la durabilidad del guante.

Las diferentes pieles de animales también influyen en las características de los guantes:

Cuero Resistente, duradero y resistente al agua. Ofrece excelente resistencia a la abrasión y comodidad.

Piel de cerdo Suave y transpirable. Se mantiene suave incluso mojado y ofrece buena durabilidad.

Piel de carnero Extremadamente suave y ligero. Permite una gran destreza y es impermeable.

Piel de cabra Resistente y flexible. Resiste desgarros y agua, lo que lo hace cómodo para un uso prolongado.

De gamuza Suave y flexible. Ofrece gran destreza, pero es menos duradero que otros tipos.

piel de búfalo Grueso y muy duradero. Ofrece una resistencia superior a la abrasión y se adapta a la mano con el paso del tiempo.

Cuero de caballo Resistente y duradero. Se vuelve más cómodo a medida que se adapta.

Nota: El tipo de cuero utilizado en los guantes puede afectar la comodidad, la protección y el ajuste del guante a lo largo del tiempo.

Los guantes de piel flor destacan por su durabilidad. Resisten el desgaste, lo que los hace ideales para trabajos exigentes. Con el tiempo, estos guantes desarrollan una pátina, un acabado único que les aporta carácter y muestra su historia. Muchos trabajadores valoran esta característica porque refleja tanto calidad como durabilidad. Los guantes de serraje ofrecen flexibilidad y ahorro, pero su durabilidad puede ser menor que la de las opciones flor.

Los guantes sintéticos utilizan una gama de materiales que imitan o mejoran el cuero natural. El cuero vegano de Faux Leathers representa una nueva generación de materiales ecológicos. opciones basadas en plantas Elaborados con materiales como piña, cactus y uva, reducen la necesidad de productos animales. Además, utilizan menos agua y tierra que el cuero tradicional. Muchos consumidores eligen el cuero vegano para apoyar el bienestar animal y reducir su huella de carbono.

Consejo: Los cueros veganos de origen vegetal siguen mejorando en sostenibilidad y rendimiento. Elegir productos de fuentes confiables garantiza los mejores beneficios ambientales.

El impacto ambiental de los materiales sintéticos varía. Los cueros veganos a base de plástico tienen una menor huella de carbono que el cuero animal. Sin embargo, algunas versiones sintéticas, como el PU, utilizan petroquímicos. Las alternativas vegetales ofrecen una solución más sostenible.

Los guantes sintéticos ofrecen varias ventajas para trabajos exigentes. Los fabricantes utilizan materiales como látex, nitrilo, neopreno y PVC para crear guantes con resistencias específicas:

Caucho de látex Ofrece excelente resistencia a la abrasión, cortes y desgarros. Ofrece un agarre firme para manipular materiales afilados.

Nitrilo Resistente a disolventes y productos químicos peligrosos. Ofrece mayor resistencia al corte y a la abrasión, y es hipoalergénico.

Neopreno Protege contra una amplia gama de productos químicos. Ofrece una excelente resistencia táctil para tareas precisas.

CLORURO DE POLIVINILO Ofrece una resistencia económica a aceites y ácidos. Resiste bien la abrasión y es ideal para diversos trabajos de manipulación de productos químicos.

Los guantes sintéticos suelen destacar por su flexibilidad y versatilidad. Se adaptan a diferentes entornos de trabajo, desde obras de construcción hasta laboratorios. Muchos trabajadores prefieren opciones sintéticas para tareas que requieren alta destreza o exposición a productos químicos.

Los guantes de trabajo son fundamentales para la seguridad en trabajos pesados. Los trabajadores confían en ellos para protegerse de diversos peligros. Entre sus características más importantes se incluyen el acolchado protector, el aislamiento, la impermeabilidad, la flexibilidad y el agarre. Estas características ayudan a prevenir lesiones y a mantener las manos cómodas durante tareas exigentes.

Acolchado protector Protege las manos de cortes y abrasiones.

El aislamiento mantiene las manos calientes en ambientes fríos.

La impermeabilización protege contra la humedad.

La construcción flexible permite destreza.

El agarre mejora el manejo de herramientas y materiales.

Al seleccionar guantes, los trabajadores deben considerar la protección contra descargas eléctricas y exposición a sustancias químicas. Los guantes también deben mejorar el agarre para manipular objetos pesados o resbaladizos. El aislamiento es esencial para condiciones climáticas extremas. Estas características garantizan la seguridad y la eficiencia en el trabajo.

|

Característica |

Descripción |

|---|---|

|

Durabilidad |

Los guantes altamente duraderos brindan protección continua y resisten el desgaste en condiciones intensivas. |

|

Espesor |

Los guantes más gruesos ofrecen mayor resistencia química pero pueden reducir la flexibilidad. |

|

Ajuste y comodidad |

Los guantes cómodos fomentan el uso constante y mejoran la movilidad de los dedos, reduciendo la fatiga y el riesgo de lesiones. |

|

Resistencia química |

Los guantes deben elegirse en función de los productos químicos específicos a los que están expuestos los trabajadores, garantizando así una protección adecuada. |

|

Aislamiento |

Importante para ambientes fríos, evitando que las manos se congelen durante el trabajo. |

|

Impermeabilización |

Esencial para trabajadores expuestos a condiciones húmedas, asegurando que sus manos permanezcan secas. |

|

Agarre |

Un agarre mejorado ayuda a manipular herramientas y materiales de manera eficaz. |

|

Protección contra impactos |

El acolchado puede proteger contra cortes, abrasiones e impactos, lo cual es crucial para la seguridad en trabajos difíciles. |

La protección contra impactos y la resistencia a la abrasión son fundamentales para la seguridad en entornos difíciles. guantes de cuero Los guantes sintéticos se someten a pruebas de resistencia a la abrasión con el abrasivo de plataforma rotatoria Taber, según la norma ASTM D7255. Estas pruebas miden el número de ciclos necesarios para desgastar el cuero. Cada tipo de cuero, ya sea de vaca, cerdo o cabra, presenta propiedades únicas de resistencia al desgaste. Los guantes sintéticos también se someten a pruebas similares, lo que permite una comparación directa de su rendimiento.

La protección contra impactos se consigue gracias al acolchado reforzado del diseño del guante. Este acolchado absorbe los impactos y reduce el riesgo de lesiones por caída de objetos o maquinaria. Los trabajadores de la construcción, la manufactura y otros sectores de alto riesgo dependen de guantes con una sólida protección contra impactos para su seguridad diaria.

Nota: Los guantes con agarre mejorado y protección contra impactos ayudan a los trabajadores a manipular herramientas y materiales de forma segura, incluso en condiciones resbaladizas o peligrosas.

La resistencia al corte y a la perforación es esencial para la seguridad en trabajos con herramientas o materiales afilados. Las normas de la industria, como los niveles de corte ANSI, ayudan a los trabajadores a elegir los guantes adecuados para sus tareas. La siguiente tabla compara los niveles de resistencia al corte ANSI de cuatro guantes de trabajo con recubrimiento de nitrilo:

Los guantes de cuero suelen incluir un forro resistente a perforaciones para mayor protección. Los guantes sintéticos, especialmente los de HPPE y para-aramidas, ofrecen una alta resistencia a las perforaciones. El tejido más denso y el recubrimiento de la palma aumentan la protección al reducir los espacios para objetos afilados. Un fino recubrimiento de la palma mantiene el hilo unido, evitando el movimiento y mejorando la seguridad.

Los trabajadores siempre deben adaptar las características de protección de los guantes a los riesgos a los que se enfrentan. Una selección adecuada garantiza la seguridad, reduce el riesgo de lesiones y fomenta la productividad en entornos de trabajo exigentes.

El ajuste y la flexibilidad son fundamentales para el rendimiento de los guantes de trabajo en trabajos exigentes. Los trabajadores necesitan guantes que permitan a sus manos moverse libremente y sujetar las herramientas con seguridad. Los guantes de cuero suelen amoldarse a la forma de la mano con el tiempo, proporcionando un ajuste personalizado. Los guantes sintéticos utilizan diseños avanzados para mejorar la destreza y la comodidad desde el principio. Muchos fabricantes añaden dedos precurvados a los guantes sintéticos, lo que ayuda a crear un ajuste natural y aumenta la destreza.

La siguiente tabla destaca las características ergonómicas que contribuyen al ajuste y la flexibilidad en guantes de cuero y sintéticos:

|

Característica |

Beneficio |

|---|---|

|

Mayor destreza y flexibilidad |

Permite un mejor movimiento y manejo. |

|

Agarre mejorado |

Garantiza un manejo seguro en diversas condiciones. |

|

Calidad constante |

Reduce problemas como imperfecciones o encogimiento. |

|

Peso más ligero |

Aumenta la comodidad y la usabilidad. |

|

Material transpirable |

Mejora la comodidad durante el uso prolongado. |

Los guantes sintéticos suelen incluir dorsos de spandex ligeros y elásticos. Este diseño aumenta la destreza y hace Los guantes son más cómodos durante largos periodos. La compatibilidad con pantallas táctiles es otra característica de muchos guantes sintéticos, lo que permite a los trabajadores usar dispositivos sin quitárselos. Los guantes de cuero, aunque más pesados, ofrecen protección y comodidad fiables para trabajos que requieren un agarre firme y durabilidad.

Consejo: Los trabajadores deben elegir guantes que equilibren la destreza con la protección y la comodidad para obtener los mejores resultados en el trabajo.

La transpirabilidad influye en la comodidad de los guantes durante un uso prolongado. Los guantes de cuero, especialmente los de piel de cerdo o de cabra, permiten la circulación del aire y ayudan a mantener las manos frescas. Los guantes sintéticos suelen usar malla o elastano en el dorso de la mano. Estos materiales aumentan la transpirabilidad y reducen la acumulación de sudor.

Los trabajadores que necesitan guantes para turnos largos se benefician de los diseños transpirables. Estos guantes ayudan a prevenir la irritación y las molestias de la piel. Muchos guantes sintéticos utilizan tejidos que absorben la humedad para mantener las manos secas. Los guantes de cuero con perforaciones o pieles más suaves también mejoran la circulación del aire. La transpirabilidad favorece la destreza, la protección y la comodidad, lo que la convierte en un factor clave en la selección de guantes.

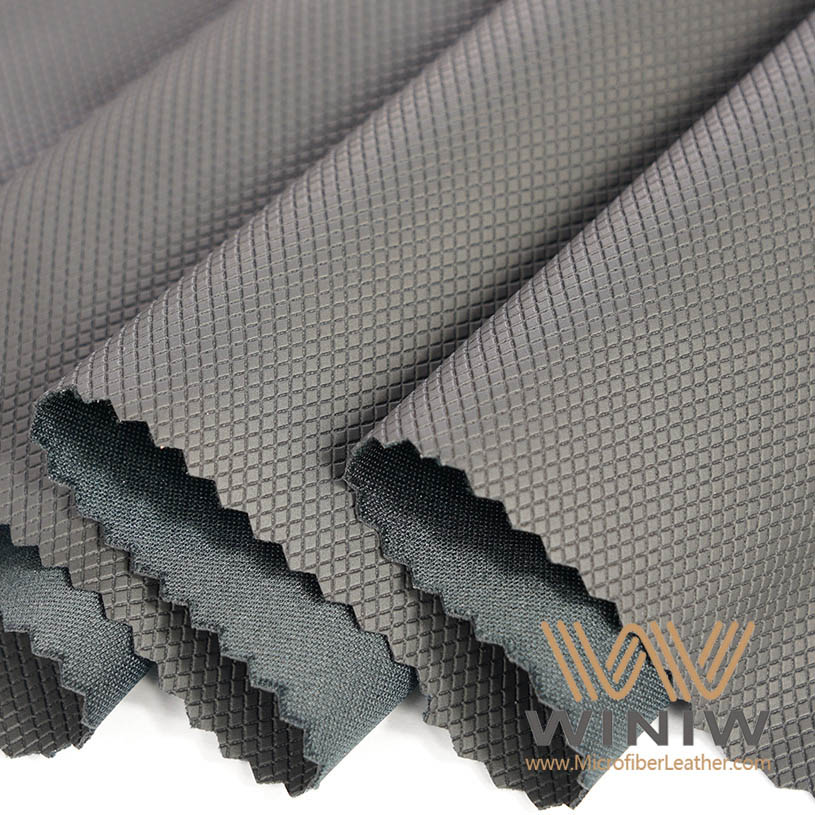

Guantes de piel sintética y piel vegana. características de comodidad únicas Para tareas exigentes. Muchos guantes de cuero vegano incluyen nudillos y palmas acolchados. Este acolchado proporciona mayor protección y comodidad durante trabajos pesados. Las puntas de los dedos reforzadas aumentan la durabilidad y ayudan a mantener un ajuste seguro. Los trabajadores que usan estos guantes para jardinería o construcción aprecian su excelente agarre y diseño ergonómico.

Los guantes de cuero vegano de Faux Leathers combinan materiales ligeros con una construcción flexible. Estos guantes favorecen la destreza y reducen la fatiga de las manos. Los materiales vegetales utilizados en el cuero vegano también ofrecen una sensación suave al tacto. Los trabajadores disfrutan de protección y comodidad, incluso durante largas jornadas. Faux Leathers continúa innovando, ofreciendo guantes que satisfacen las necesidades de los profesionales modernos.

Los guantes de cuero tienen fama de resistir las condiciones más duras. Muchos trabajadores los eligen para trabajos que exigen resistencia y resiliencia. Con un uso intensivo, estos guantes suelen durar entre 1 y 2 años. Con un uso menos intenso y un cuidado adecuado, su vida útil puede extenderse de 3 a 5 años. Esta durabilidad se debe a la dureza natural del material y a la forma en que desarrolla una pátina protectora con el tiempo. Esta pátina no solo le aporta carácter, sino que también ayuda a proteger los guantes del desgaste. Los trabajadores suelen notar que los guantes bien mantenidos se vuelven más cómodos y flexibles con el tiempo.

Los guantes de trabajo de cuero pueden durar aproximadamente entre 1 y 2 años con un uso intensivo.

Con un cuidado adecuado y un uso menos intenso, pueden durar entre 3 y 5 años.

El envejecimiento no siempre implica pérdida de funcionalidad. Muchos profesionales valoran la forma en que estos guantes se adaptan a la mano, mejorando el agarre y la comodidad con cada uso.

Los guantes sintéticos ofrecen flexibilidad y resistencia a muchos productos químicos, pero su La durabilidad depende del cuidado regular Los trabajadores pueden prolongar la vida útil de los guantes sintéticos siguiendo unos sencillos pasos:

Limpie los guantes después de cada uso. La suciedad y la humedad pueden causar un desgaste prematuro. Use jabón suave y agua tibia para guantes de tela. Para cuero sintético, un paño húmedo es la mejor opción.

Seque los guantes al aire. Evite el calor directo, ya que puede deteriorar los materiales o provocar encogimiento.

Guarde los guantes en un lugar fresco y seco. Manténgalos alejados de la luz solar y la humedad. Extenderlos o colgarlos ayuda a mantener su forma.

Alterne entre varios pares. Esta práctica permite que cada par se recupere y reduce el desgaste general.

Inspeccione los guantes regularmente. Busque señales de daño y reemplace los guantes que ya no ofrezcan protección.

Consejo: El mantenimiento constante no solo prolonga la vida útil de los guantes, sino que también garantiza la seguridad en el trabajo.

Los guantes de cuero vegano, especialmente los elaborados con materiales vegetales como piña, cactus o uva, se han popularizado por su equilibrio entre sostenibilidad y resistencia. Estos guantes resisten el desgaste, lo que los hace ideales para tareas exigentes. Los fabricantes diseñan el cuero vegano para resistir la abrasión, la humedad y el uso frecuente. Muchos usuarios comprueban que estos guantes mantienen su aspecto y flexibilidad con el tiempo. La ligereza del cuero vegano también ayuda a reducir la fatiga de las manos durante largas jornadas. Con el cuidado adecuado, los guantes de cuero vegano pueden ofrecer una vida útil similar a la de las opciones tradicionales, a la vez que respetan los valores ecológicos.

|

Tipo de guante |

Vida útil típica (uso intensivo) |

Necesidades de mantenimiento |

|---|---|---|

|

Cuero |

1–2 años |

Acondicionamiento, limpieza |

|

Sintético |

6–18 meses |

Limpieza regular, secado y almacenamiento. |

|

Cuero vegano |

1–2 años |

Limpieza suave, secado al aire. |

La selección de los guantes de trabajo adecuados depende de las exigencias de cada trabajo. Los trabajadores de la construcción, la soldadura y la industria pesada suelen elegir guantes de cuero. Estos guantes ofrecen una protección eficaz contra abrasiones, cortes y calor. Muchos profesionales confían en... piel de vaca, piel de ciervo, piel de cabra , o guantes de piel de cerdo por sus cualidades únicas. Por ejemplo, la piel de vaca ofrece resistencia, mientras que la piel de cabra proporciona flexibilidad y comodidad. Los guantes de cuero resisten altas temperaturas y superficies rugosas, lo que los convierte en la mejor opción para trabajos pesados.

Los guantes sintéticos son ideales para quienes manipulan productos químicos o líquidos. Ofrecen mayor resistencia química que el cuero. Muchos técnicos de laboratorio, personal de limpieza y trabajadores de plantas químicas prefieren los materiales sintéticos. Los guantes sintéticos también son adecuados para trabajos que requieren el lavado frecuente de manos o la exposición a aceites. Los trabajadores se benefician de la flexibilidad y la ligereza de los guantes sintéticos en estos entornos.

Los guantes de cuero se destacan por su durabilidad y resistencia al calor.

Los guantes sintéticos proporcionan una protección química superior.

Diferentes tipos de cuero se adaptan a requisitos laborales específicos.

Los trabajadores siempre deben adaptar el material de los guantes a los peligros y tareas que enfrentan para lograr una seguridad y un rendimiento óptimos.

Los guantes de trabajo deben cumplir estrictas normas de seguridad para proteger a los usuarios en entornos hostiles. Organizaciones como ANSI y EN establecen directrices para el rendimiento de los guantes. Estas normas miden la resistencia de los guantes a cortes, abrasiones, perforaciones y productos químicos. La siguiente tabla resume las principales propiedades de rendimiento:

|

Propiedad de rendimiento |

Descripción |

|---|---|

|

Resistencia al corte |

Mide el peso necesario para cortar el material del guante con una cuchilla. |

|

Resistencia a la abrasión |

Refleja la durabilidad de los guantes bajo tensión abrasiva. |

|

Resistencia a la perforación |

Indica la capacidad del guante para soportar fuerzas de perforación. |

|

Resistencia química |

Evalúa la protección del guante contra la exposición química. |

Los fabricantes prueban los guantes para garantizar que cumplan con estos requisitos. Los trabajadores deben revisar las etiquetas de los productos para verificar su conformidad con las normas pertinentes. Elegir guantes que cumplan o superen estos estándares ayuda a reducir el riesgo de lesiones en el trabajo.

Las consideraciones ambientales influyen en la elección entre guantes de cuero, sintéticos y veganos. El cuero sintético destaca por sus bajas emisiones de carbono y su menor consumo de agua. Los fabricantes utilizan menos productos químicos en la producción de guantes sintéticos, lo que reduce la huella ambiental. Algunos cueros sintéticos, como los de AX Materials, utilizan material reciclado y cuentan con la certificación RCS. Esta certificación verifica el uso de materiales reciclados, lo que contribuye a los objetivos de sostenibilidad.

El cuero natural requiere un proceso de teñido y procesamiento químico exhaustivo. Estos pasos incrementan el uso de agua y productos químicos, lo que genera preocupación ambiental. El cuero vegano, especialmente las opciones de origen vegetal, ofrece una alternativa ecológica. Marcas como Faux Leathers utilizan materiales innovadores como piña, cactus y uva para crear guantes duraderos con un impacto mínimo en el planeta.

Cuero sintético Reduce las emisiones de carbono y el uso de agua.

Los cueros sintéticos certificados por RCS apoyan los esfuerzos de reciclaje.

Los cueros veganos de origen vegetal ofrecen una opción sostenible y libre de animales.

Los trabajadores y las empresas con conciencia ecológica pueden elegir guantes que se alineen con sus valores teniendo en cuenta tanto el rendimiento como el impacto ambiental.

Los guantes de cuero siguen siendo una opción popular para trabajos exigentes debido a su resistencia natural y propiedades protectoras. Los trabajadores suelen elegirlos para tareas que exigen durabilidad y resistencia a los riesgos.

Ventajas:

Aísla del frío y del viento, proporcionando protección contra la intemperie.

Resiste el desgaste y ofrece un rendimiento duradero.

Protege las manos de llamas, calor, abrasiones y pinchazos.

Se adapta a la mano con el tiempo, creando un ajuste cómodo.

Permite cierta transpirabilidad, manteniendo las manos más frescas durante el uso.

Desventajas:

Absorbe aceites y disolventes, lo que reduce la resistencia química.

Requiere limpieza y acondicionamiento regulares para mantener la calidad.

El cuero grueso puede limitar la motricidad fina y la destreza.

Costo inicial más alto en comparación con muchas opciones sintéticas.

|

Ventajas de los guantes de trabajo de cuero |

Desventajas de los guantes de trabajo de cuero |

|---|---|

|

Construcción duradera y de larga duración. |

Mala resistencia química |

|

Resistencia a la abrasión y a las perforaciones |

Altos requisitos de mantenimiento |

|

Ajuste cómodo que se adapta a la mano. |

Destreza limitada |

|

Transpirabilidad natural |

Alto costo inicial |

Nota: Los guantes de cuero funcionan mejor para trabajos que necesitan protección fuerte y durabilidad, pero pueden no ser adecuados para tareas que involucran productos químicos o que requieren movimientos precisos de los dedos.

Los guantes sintéticos ofrecen una experiencia moderna Una alternativa para muchas industrias. Los fabricantes diseñan estos guantes para satisfacer necesidades específicas, como la resistencia química o la flexibilidad.

|

Ventajas de los guantes sintéticos |

Desventajas de los guantes sintéticos |

|---|---|

|

Precio más bajo, asequible para presupuestos reducidos. |

Menos duradero en condiciones adversas |

|

Características versátiles como resistencia química y recubrimientos impermeables. |

Mala resistencia al calor, puede derretirse o degradarse a altas temperaturas. |

Los guantes sintéticos ofrecen varias ventajas:

Asequible para trabajadores y empresas con presupuestos ajustados.

Resisten productos químicos y agua, lo que los hace adecuados para laboratorios y trabajos de limpieza.

Ligero y flexible, soporta tareas que requieren destreza.

Sin embargo, los guantes sintéticos también tienen inconvenientes:

Se desgasta más rápido que el cuero en entornos exigentes.

No protege bien contra el calor o las llamas.

Consejo: Los guantes sintéticos son adecuados para trabajos que involucran productos químicos o requieren cambios frecuentes de guantes, pero es posible que no duren tanto como el cuero en condiciones difíciles.

Los guantes de cuero vegano de Faux Leathers utilizan materiales de origen vegetal para crear una opción sostenible y cómoda. Estos guantes son ideales para quienes valoran los productos ecológicos y el diseño moderno.

|

Ventajas |

Desventajas |

|---|---|

|

Flexibilidad |

Durabilidad |

|

Comodidad |

Transpirabilidad |

|

Facilidad de mantenimiento |

Impacto ambiental |

|

Más delgado y más flexible |

No es tan duradero como el cuero real. |

|

Lavable |

No respira ni se estira. |

|

No se endurece al secarse. |

Requiere combinación con otros materiales para un mejor ajuste. |

Los beneficios clave incluyen:

Flexible y ligero, lo que permite un fácil movimiento.

Cómodo de llevar durante largos periodos.

Fácil de limpiar y mantener.

No se endurece después del secado, a diferencia de algunos cueros tradicionales.

Existen algunas limitaciones:

Puede que no dure tanto como el cuero real en tareas pesadas.

Ofrece menos transpirabilidad y elasticidad.

A veces es necesario combinarlo con otros materiales para lograr el mejor ajuste.

El cuero vegano de Faux Leathers ofrece un equilibrio entre comodidad, flexibilidad y sostenibilidad, lo que lo convierte en una opción sólida para quienes desean reducir su impacto ambiental mientras se mantienen protegidos en el trabajo.

Los guantes de cuero ofrecen el máximo rendimiento para trabajos exigentes, ofreciendo una resistencia inigualable a la abrasión y a la perforación gracias a sus fibras densas y su fabricación en serraje. Los guantes sintéticos ofrecen flexibilidad y transpirabilidad, pero no ofrecen la protección necesaria para trabajos pesados. El cuero vegano de Faux Leathers destaca por su respeto al medio ambiente y comodidad, ideal para quienes valoran la sostenibilidad.

|

Tipo de material |

Durabilidad |

Comodidad |

Mejor uso |

|---|---|---|---|

|

Cuero |

Alto |

Alto |

Abrasión, calor y punción |

|

Sintético |

Moderado |

Moderado |

Destreza, resistencia química |

|

Cuero vegano |

Variable |

Alto |

Ajuste cómodo y ecológico. |

Los trabajadores deben elegir los guantes de acuerdo con los riesgos laborales y sus valores personales.

Aquellos que buscan opciones sustentables y de alto rendimiento pueden explorar los guantes de cuero vegano de Faux Leathers para obtener más información y opciones de productos.

Los guantes de trabajo de cuero son ideales para la construcción, la soldadura, el paisajismo y la operación de maquinaria pesada. Los trabajadores los eligen para tareas que requieren gran resistencia a la abrasión, protección contra el calor y durabilidad. Estos guantes resisten bien las superficies rugosas y las altas temperaturas.

Los trabajadores deben lavar los guantes sintéticos con jabón suave y agua tibia. El secado al aire ayuda a mantener la forma y la flexibilidad. Evite la luz solar directa o las fuentes de calor. La limpieza regular prolonga la vida útil de los guantes y protege las manos.

Cuero vegano Los guantes ofrecen buena durabilidad para diversas tareas. Los materiales vegetales resisten el desgaste y la humedad. Para trabajos extremadamente duros, el cuero auténtico puede durar más. El cuero vegano es ideal para quienes valoran la sostenibilidad y la comodidad.

Los guantes sintéticos suelen ofrecer una alta resistencia química. Materiales como el nitrilo y el neopreno bloquean muchas sustancias peligrosas. Por esta razón, los trabajadores de laboratorios, limpieza o plantas químicas suelen elegir guantes sintéticos.

Algunos guantes de cuero vegano utilizan materiales reciclables de origen vegetal. El reciclaje depende de las instalaciones locales y del diseño específico del guante. Consulte siempre las etiquetas del producto y las directrices locales de reciclaje para obtener información precisa.

Características como palmas acolchadas, tejidos transpirables y diseños ergonómicos aumentan la comodidad. Los materiales ligeros y la construcción flexible ayudan a reducir la fatiga de las manos. Muchos guantes modernos incluyen forros que absorben la humedad para mayor comodidad.

Los trabajadores deben medir el ancho y largo de la mano y compararlos con la tabla de tallas del fabricante. Un ajuste adecuado garantiza mejor protección, agarre y comodidad. Unos guantes bien ajustados reducen el riesgo de ampollas y lesiones.

Los guantes de cuero vegano de Faux Leathers son ideales para exteriores. Resisten la humedad y la abrasión. Son cómodos para trabajos de jardinería, paisajismo y construcción ligera. Además, promueven valores ecológicos.

Escanear a wechat: